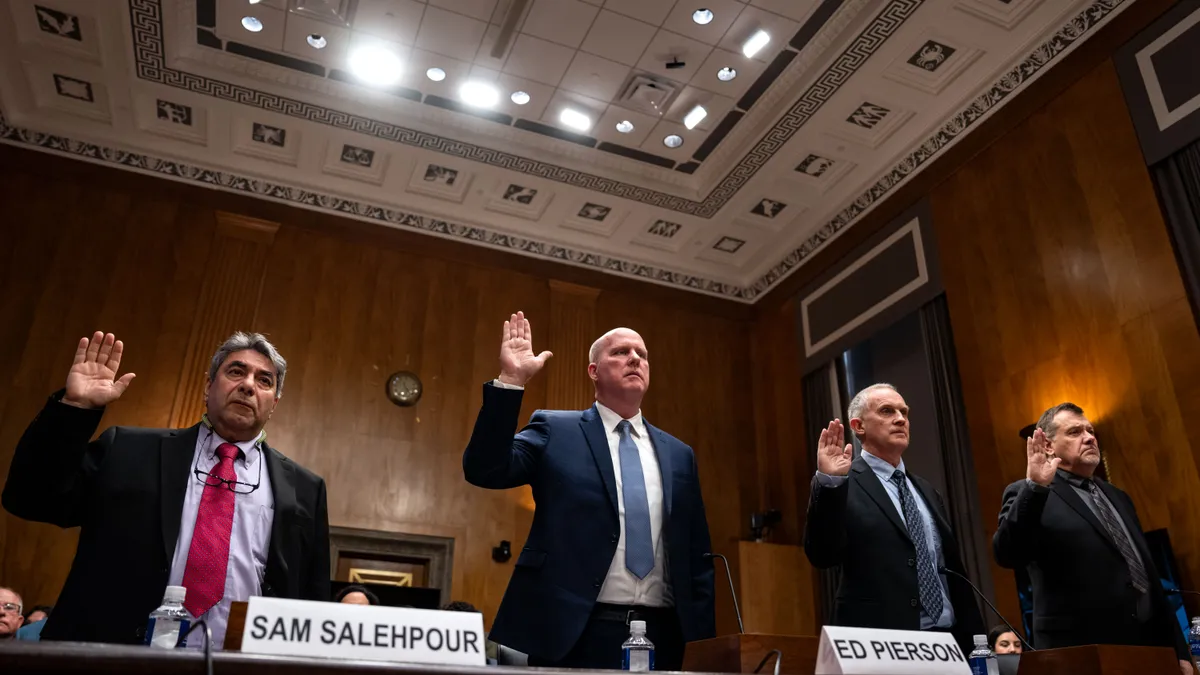

WASHINGTON — Lives are at stake if Boeing does not address its manufacturing safety issues, quality engineer turned whistleblower Sam Salehpour said during a Senate hearing Wednesday.

Salehpour was one of multiple whistleblowers who testified yesterday before the Senate Homeland Security & Governmental Affairs investigations subcommittee, blasting the aircraft maker and federal agencies for a lack of safety and accountability.

"I have observed a culture that prioritizes speed of production over safety and quality and incentivizes management to overlook significant defects in Boeing’s airplanes," Salehpour said in his testimony. "Despite what Boeing officials state publicly, there is no safety culture at Boeing and employees like me who speak up about defects with its production activities and lack of quality control are ignored, marginalized, threatened, sidelined, and worse."

The Boeing engineer said he feared for his personal safety as a result of speaking publicly. He spoke of being threatened and harassed at work after bringing concerns regarding the Max 787 and the 777 to his supervisor.

“After the threats and after this, you know, it really scares me, believe me, but I am at peace,” Salehpour said, tearing up. “Something happens to me, I am at peace because I'm coming forward. I will be saving a lot of lives."

Salehpour detailed how Boeing has taken shortcuts in its 787 production processes when it comes to fastening together aircraft pieces such as fuselages, defects that could cause planes to have premature fatigue failure without warning. He added that more than 1,000 787s could be affected by Boeing's lack of proper installation.

“Any one of these conditions can impact the joint fatigue quality and therefore can decrease the fatigue life of the airplane,” Salehpour said. “This, of course, creates extremely unsafe conditions for the aircraft with potentially catastrophic accidents and passenger fatalities.”

‘This is a criminal cover up’

Salehpour was joined by Ed Pierson, a former Boeing engineer and current executive director of the Foundation for Aviation Safety.

“Government authorities ignored Boeing's manufacturing problems until the Alaska [Airlines] accident,” Pierson told the subcommittee. “Passengers shouldn't have to rely on whistleblowers to provide the truth.”

Pierson criticized the Federal Aviation Administration, Department of Transportation and National Transportation Safety Board for creating a false illusion of safety around the U.S. aviation system.

“These agencies have become lazy, complacent, and reactive, and the deterioration has been occurring over several years," Pierson said.

Pierson noted he believes the manufacturing conditions that led to the fatal 2018 Lion Air and 2019 Ethiopia Airlines crashes also led to the Alaska Airlines blowout incident.

Pierson served as a senior manager at Boeing’s 737 factory in Renton, Washington, from 2015 to 2018 according to his LinkedIn. He described the company as home to “chaotic manufacturing” and a “dysfunctional safety culture."

Pierson noted he brought his concerns regarding the manufacturing environment to the company’s leadership, including then-President and CEO Dennis Muilenburg, and tried to get the Renton facility to shut down before both the Lion Air and Ethiopia Airlines crashes.

“People are shocked to learn about Boeing’s current production quality issues,” Pierson said. “I’m not surprised at all, because nothing changed after the two MAX crashes. If anything, conditions have only worsened.”

Regarding a supposed lack of documentation concerning the work associated with the removal of the infamous Alaska Airlines door at Boeing's Renton facility, Pierson said the documents do exist and that there was a "criminal cover-up" to conceal them.

"Records do exist documenting in detail the hectic work done on the Alaska Airlines airplane and Boeing’s corporate leaders know it too, because they fought to withhold these same damning records after the two MAX crashes," Pierson said. "I know this Alaska airplane documentation exists because I personally passed it to the FBI."

Boeing’s defective production cost lives, expert says

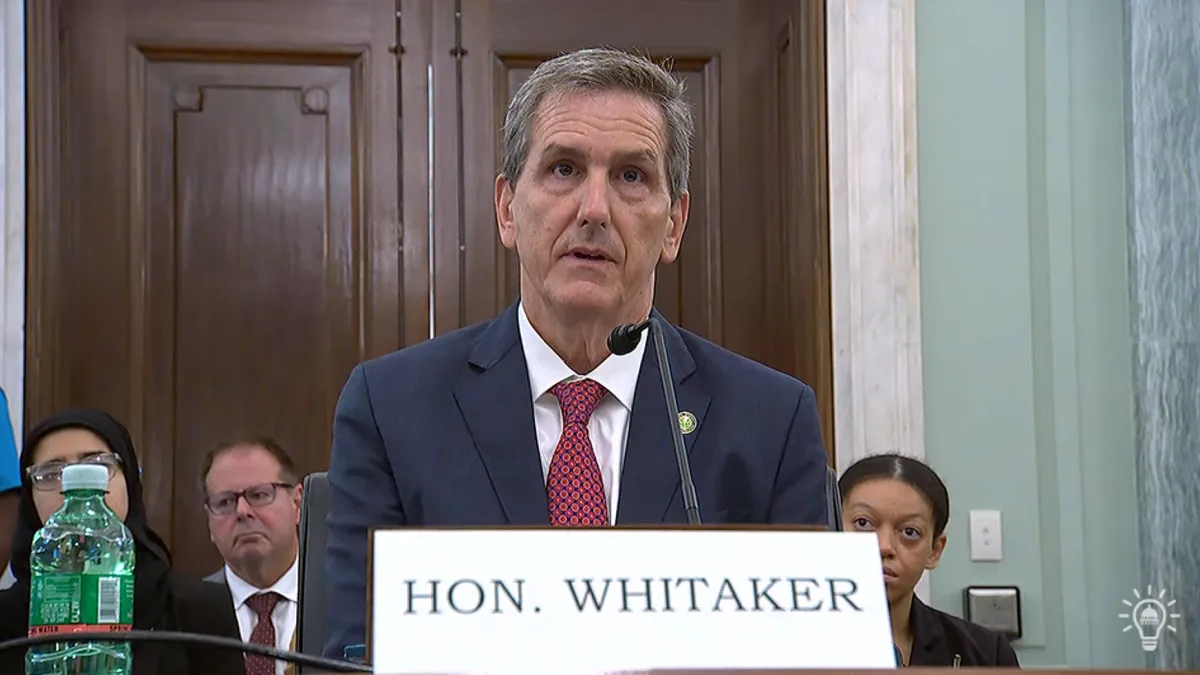

Former FAA engineer Joe Jacobsen spoke about Boeing's decision to conceal the new design of its flight stabilization software, the Maneuvering Characteristics Augmentation System, in 2018 to avoid additional certification requirements.

The flawed design, Jacobsen said, contributed to the two fatal crashes.

“Had we known, at least a half dozen experienced FAA engineers in the Seattle office would have immediately rejected the original MCAS design,” Jacobsen said. “Boeing’s concealment led to two crashes and 346 deaths.”

During the re-certification of the Max aircraft, which was completed in November 2020, Jacobsen said FAA leadership supported Boeing’s effort to primarily focus on MCAS, but other critical issues such as manufacturing defects and a non-compliant crew alerting system, were not addressed.

Jacobsen highlighted the vulnerabilities of the “grandfathered” design of the Max, which together with the company's failure to investigate its flawed manufacturing safety culture, lead to unsafe conditions.

“I’ve spent almost 40 years studying and trying to eliminate aviation accidents,” Jacobsen said. “Ignoring problems, taking short cuts, and deceiving the public leads to more crashes.”

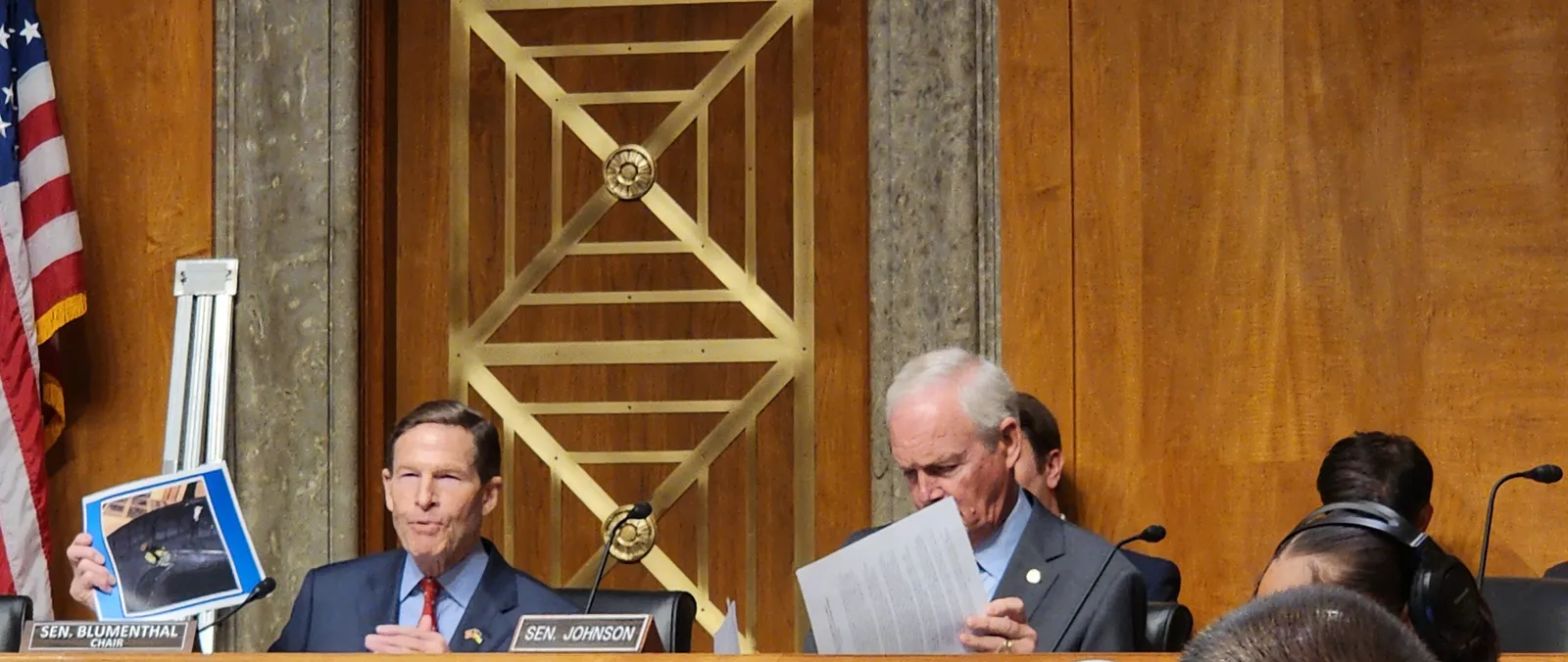

Subcommittee Chair Sen. Richard Blumenthal said that the body intends to hold multiple hearings regarding Boeing's "broken safety culture," and that more individuals have come forward since the hearing was announced. Blumenthal also noted Boeing CEO Dave Calhoun is expected to appear before lawmakers.

"We intend to uncover what has enabled the culture of safety disregard to exist, so that we can change it for good," Blumenthal said. "To create a genuine and comprehensive culture of safety, Boeing must create workplace conditions where everyone feels comfortable reporting quality and safety concerns."