Dive Brief:

- Automation company Siemens said it opened two electrical equipment manufacturing facilities in California and Texas last week as part of its smart infrastructure business.

- The company unveiled a 100,000-square-foot hub in Pomona, California, last Wednesday, the first of two phases of a $95 million expansion project, according to a press release. Siemens also opened a $190 million hub that spans 500,000 square feet in Fort Worth, Texas.

- The two plants are expected to create over 900 jobs, servicing commercial, industrial and construction markets powering infrastructure such as artificial intelligence data centers.

Dive Insight:

Siemens has been steadily investing in industrial AI in the U.S. for over two decades, building the technology’s capabilities to support digital innovation and regrowth in domestic manufacturing, Siemens USA CEO Barbara Humpton told a House subcommittee in February.

“We’ve done this because we see tremendous potential to make American industry more state-of-the-art and competitive,” Humpton said in her testimony. “Industrial AI provides opportunities for reliable, secure, trustworthy applications that help manufacturers create business value from their data. Because of Industrial AI, businesses across the country are advancing towards better products, more efficient operations, and a more prepared workforce.”

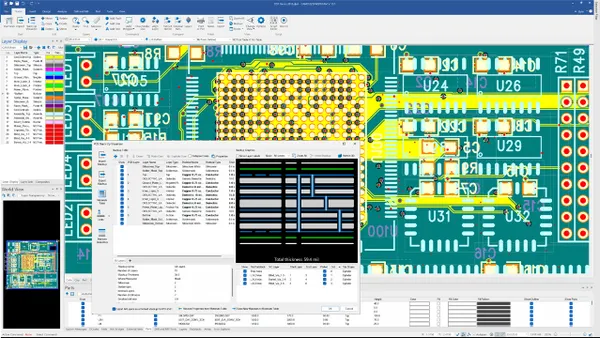

Humpton told House lawmakers last month that Siemens used industrial AI to develop a digital twin of the Fort Worth facility’s product and production lines.

“Fort Worth is a microcosm of what Industrial AI can do for domestic manufacturing,” Humpton said in her remarks. “With these technologies, we can boost economic growth, create jobs, empower innovation, and secure the next generation of American industry.”

To support its largest regional market, Siemens said it plans to invest more in U.S. manufacturing jobs, software and AI infrastructure as demand for data centers grows.

The Fort Worth hub will create electrical equipment such as low-voltage switchboards. Siemens will use its digital industries software to optimize its production flow by simulating, validating and commissioning the process so the shop floor can be designed for higher quality.

The Fort Worth site has already added 480 jobs and is on track to have a total of 800 employees by 2026, according to a release. Siemens will recruit workers from the education sector, such as teachers and principals, to train its manufacturing workforce. The company also plans to train employees from the classroom to on-hands learning in the lab before they begin working on the production floor.

The Pomona hub is located close to Siemens’ legacy electrical products facility. The second phase of the hub will rebuild the existing plant, and once complete, the two buildings combined will span 146,000 square feet, Siemens said. The hub will increase the production of low-voltage electrical equipment such as switchboards and lighting panels.

Other actions Siemens took to address growing AI infrastructure demand included acquiring Michigan-based software maker Altair Engineering in October 2024 for approximately $10 billion. The transaction is expected to close in the second half of 2025 and aims to improve the company’s digital twin infrastructure.