Redwire Corporation received a $5.9 million contract from NASA to finish designing an in-space, multi-material 3D printing system, the company announced earlier this month.

The 3D printer will enable crews to make tools, replacement parts and printed circuit boards as needed in space using materials including metal, plastics, ceramics and electronics, according to the release. The FabLab solution is expected to be tested aboard the International Space Station prior to use on Artemis missions to the Moon and Mars.

“Astronauts won’t need to pack their spacecraft with every tool or part they may need millions of miles from Earth,” Redwire’s EVP of In-Space Manufacturing and Operations John Vellinger said in a statement. “Make it, don’t take it.”

The aerospace manufacturer was selected to prototype the FabLab in 2017, but the latest contract will see the FabLab design made spaceflight ready.

Redwire is anticipating a follow-up contract to support the construction of the FabLab at the International Space Station, per the release. The pilot will inform building versions of the printers for use beyond low-Earth orbit.

“Having an integrated capability for on-demand manufacturing and repair of components and systems during space missions will be integral for sustainable exploration missions,” Jim Reuter, associate administrator for NASA Space Technology Mission Directorate programs, said in a statement.

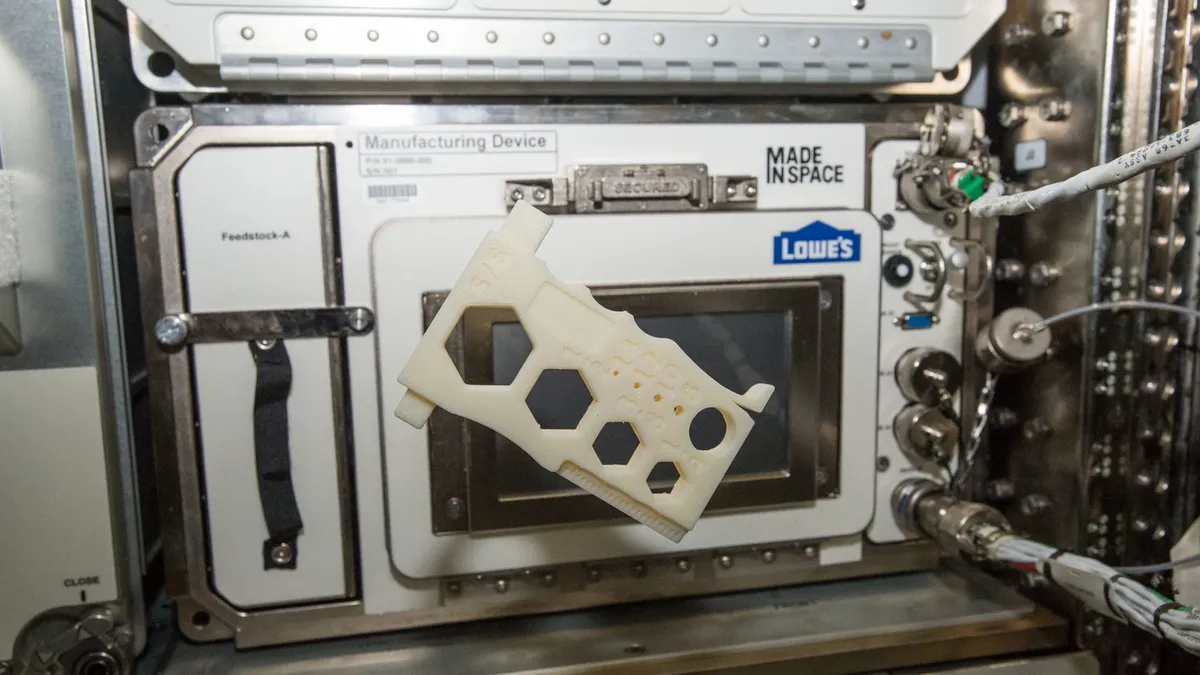

The FabLab will not be Redwire’s first manufacturing solution to reach space. The company’s launched its first commercial manufacturing platform aboard the International Space Station in 2016, which became its guide star for developing new additive capabilities for space, according to Redwire’s website.

“FabLab is a solution for some of the key logistics challenges with sustained human deep space exploration aboard the Lunar Gateway and on the Moon and Mars,” Vellinger said.