Four key bolts were missing from the Alaska Airlines 737-9 mid exit door plug that blew out midair on Jan. 5, according to an initial investigative report from the National Transportation Safety Board out this week.

The bolts, which should have prevented the door from moving, were removed and seemingly not replaced during repairs at Boeing’s Renton, Washington, factory.

The mid exit door plug was produced by Spirit AeroSystems in Malaysia in March 2023, and it was installed onto the fuselage in May 2023 at Spirit’s factory in Wichita, Kansas. The aircraft fuselage was then shipped to Boeing’s facility in Renton, Washington, arriving at the site on Aug. 31, 2023.

Before shipping the 737-9 Max aircraft to Boeing’s Renton facility, Spirit workers noted a minor nonconformity in the seal flushness of the door plug, but determined no re-work was needed because the part was structurally sound.

Once the part arrived at Boeing’s factory, teams there noted damage to five rivets on the edge frame of the left door plug, requiring repairs. In mid-September, Spirit personnel worked at the Boeing plant to open the door plug, which was required to repair the rivets, removing the four bolts to do so. Boeing records and employee photos show that the rivets were replaced, but the bolts were not.

The report found no evidence that the door plug was opened again after this point, before it was shipped to Alaska Airlines. Boeing has not disclosed to the NTSB who re-opened and closed the door plug or who authorized the repairs and signed off on the process.

In response to the NTSB report, Boeing President and CEO Dave Calhoun said on Tuesday the aircraft maker is accountable for the Alaska Airlines incident.

“An event like this must not happen on an airplane that leaves our factory. We simply must do better for our customers and their passengers,” Calhoun said in a statement.

Spirit said in a statement that it remains focused on working closely with Boeing and regulators to improve its processes and meet the highest standard of safety, quality and reliability.

Calhoun noted that Boeing launched a plan to improve and strengthen Boeing’s 737 production system. The aircraft maker has started a control plan that ensures all 737-9 MED plugs are installed according to specifications. Boeing also set up new inspections of the door plug assembly and other similar structures at Spirit’s factory, as well as its own production line.

Boeing will also add signage and protocol to document when a door plug is opened or removed at its factory, ensuring it is properly reinstalled and inspected before delivery. Other actions include:

- Increase inspections of its supply chain and supplier collaborations

- Carry out more work on the planes at their assigned positions

- Devote multiple days for the 737 teams to focus on and establish quality improvements

- Establish an independent evaluation to boost the quality management system at Boeing Commercial Airplanes by an experienced safety expert

Finally, Boeing will open its factory to its 737 customers to perform their own reviews.

“It will take significant, demonstrated action and transparency at every turn – and that is where we are squarely focused,” Calhoun said in a statement.

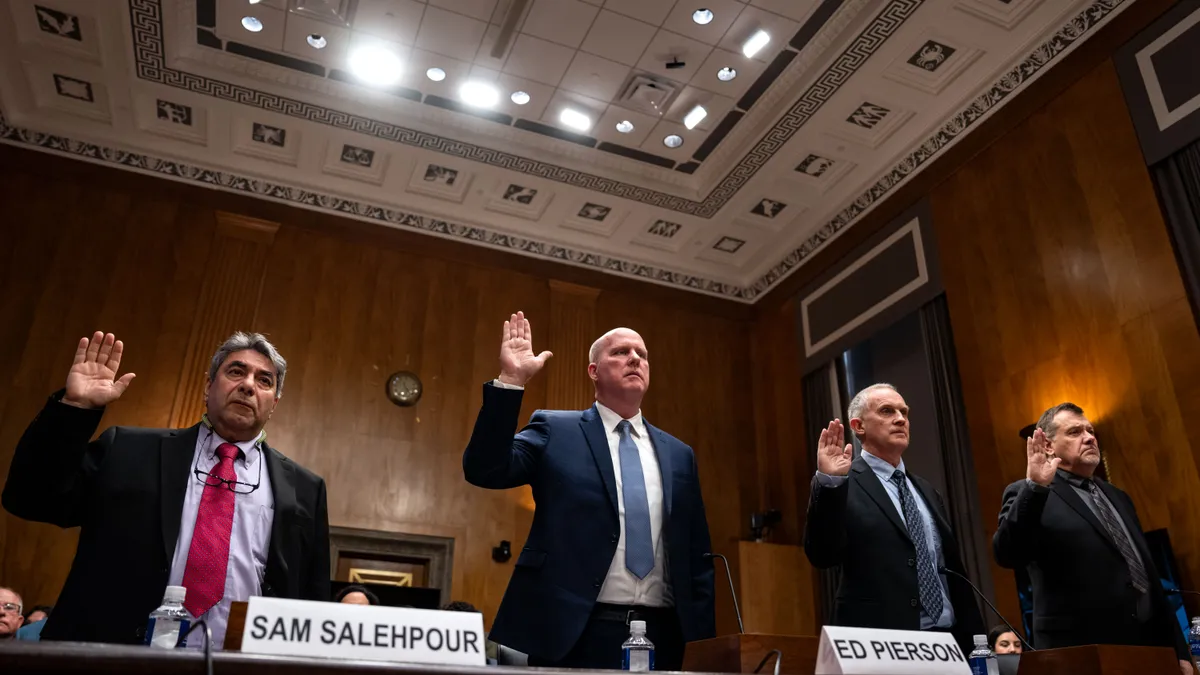

The NTSB plans to interview Boeing and Spirit workers in the future. In the meantime, the federal agency will review Boeing’s safety management system, as well as Spirit’s developing safety management system program, according to the report.

NTSB will also evaluate the Federal Aviation Administration’s involvement in the companies’ SMS programs and how much oversight is applied to each SMS plan.

Tuesday was a busy day for Spirit, one of Boeing’s key suppliers. CEO and President Pat Shanahan attempted to assuage concerns during an earnings call Tuesday that the aerospace parts maker is increasing oversight of its manufacturing processes to ensure quality and safety.

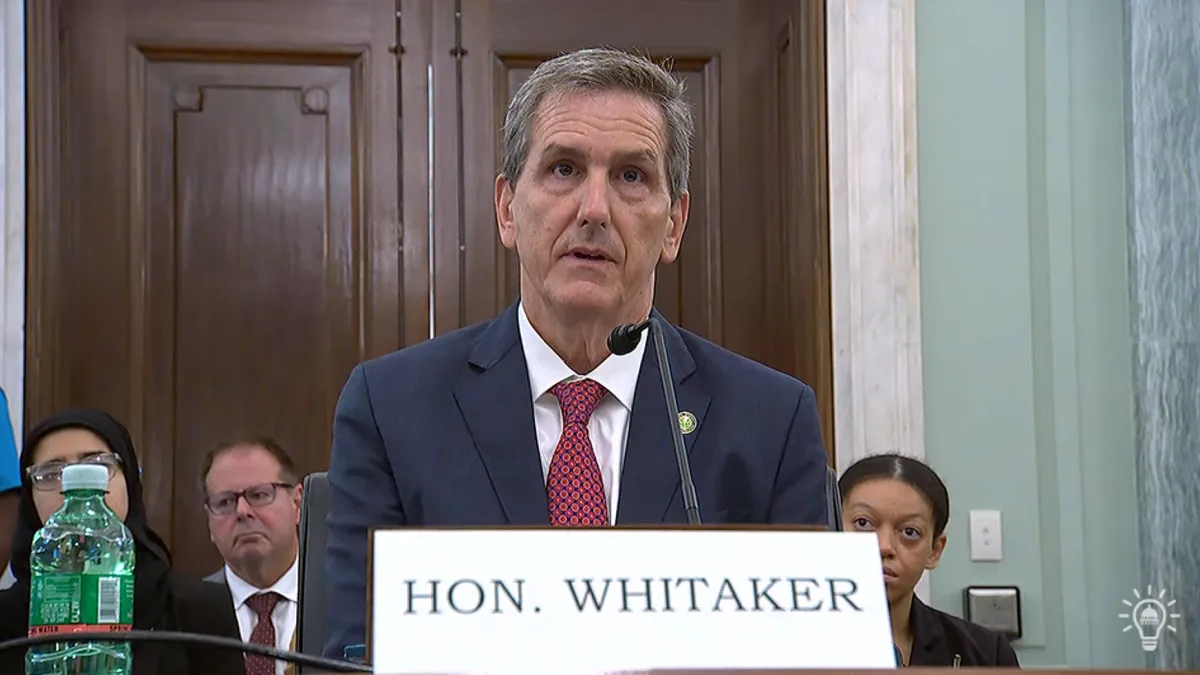

The same day, FAA Administrator Michael Whitaker testified before Congress regarding the agency’s actions in the Alaska Airlines incident. The FAA has increased its oversight of Boeing’s production and manufacturing and plans to audit the company’s 737-9 Max production line and those of its suppliers.

“Let me stress: we will follow the data and take appropriate and necessary action,” Whitaker told lawmakers. “We will continue to implement the Aircraft Certification, Safety, and Accountability Act as recent events underscore the importance of continuously looking for ways to improve and refine safety oversight activities.”