Dive Brief:

- Niacet Specialty Chemicals is investing $50 million to expand its facility in Niagara Falls, New York, to service the state’s semiconductor supply chain, Gov. Kathy Hochul announced May 17.

- The funds will go toward building a 25,000-square-foot facility, creating new jobs as well as renovating two other facilities at the Niagara Falls site, according to county documents.

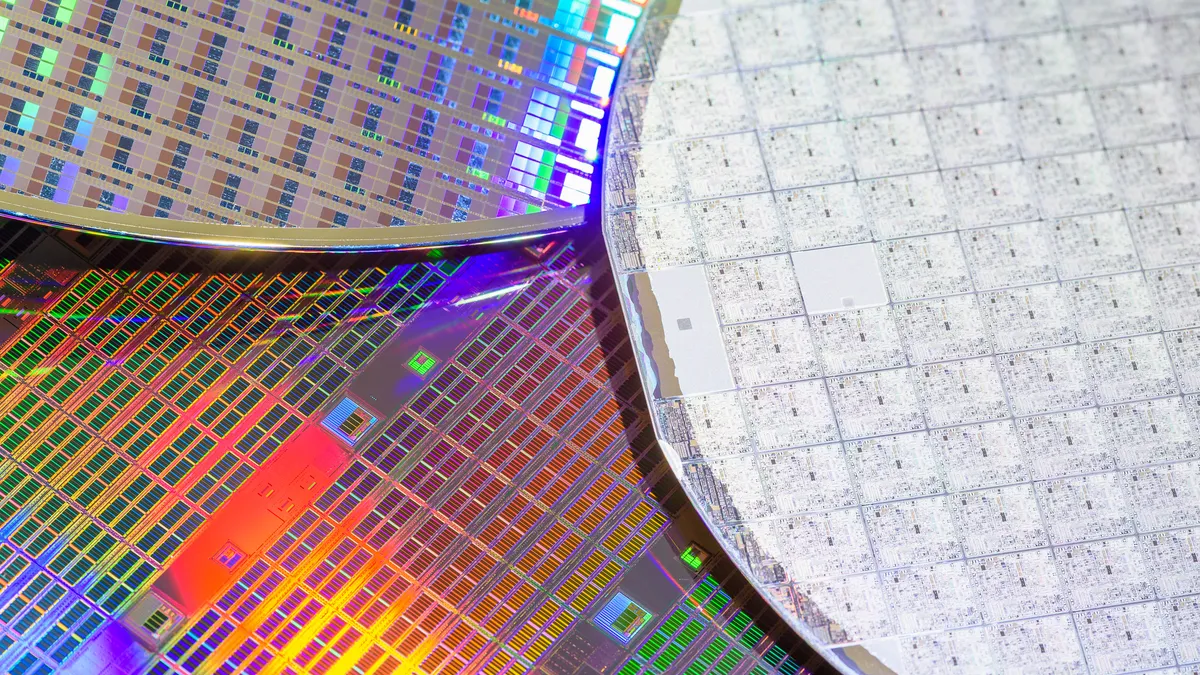

- Niacet produces anhydrous hydrogen chloride, a critical substance semiconductor manufacturers use to create thin crystalline silicon layers on wafers and imprint crystals.

Dive Insight:

Niacet is a subsidiary of Kerry Group, an Ireland-based food ingredient and supplement maker that acquired the chemical company in 2021.

Niacet also produces food preservation products and has another facility in Tiel, Netherlands, which Kerry also acquired in addition to the Niagara Falls site.

Now that more semiconductor companies, particularly fabs in New York, are receiving funds through the CHIPS and Science Act, the demand for anhydrous hydrogen chloride has increased, the company stated in county documents.

“Rapid expansion is necessary to fill new demand for defense and commercial purposes,” Niacet stated. “If this demand cannot be met it will encourage foreign investment and force activity outside of the United States.”

Niacet also applied for CHIPS funding. To date, chipmakers that have received CHIPS funding in part to expand New York facilities include Micron Technology with $6.1 billion and GlobalFoundries with $1.5 billion.

On the defense industry side, GlobalFoundries has a $3.1 billion supply contract with the Department of Defense. The chipmaker is also collaborating with defense contractor Lockheed Martin on advancing semiconductors as well as increasing the protection of domestic supply chains for national security systems.

Niacet’s investment builds on Hochul’s goal to create a profitable semiconductor production hub in New York, according to the release.

Another manufacturer is supporting chip production by making dry pumps, which help remove gases and residues in the process. UK-based Edwards Vacuum broke ground on a $319 million dry pump manufacturing facility in April in Alabama.