The industrial metaverse might still sound far-off, but manufacturers are already exploring how the technology could produce new ways to cut costs and improve operations.

The idea is to use virtual technologies to enable both employees and executives to try new processes and ideas — without the risk or expense associated with experimenting in the physical world.

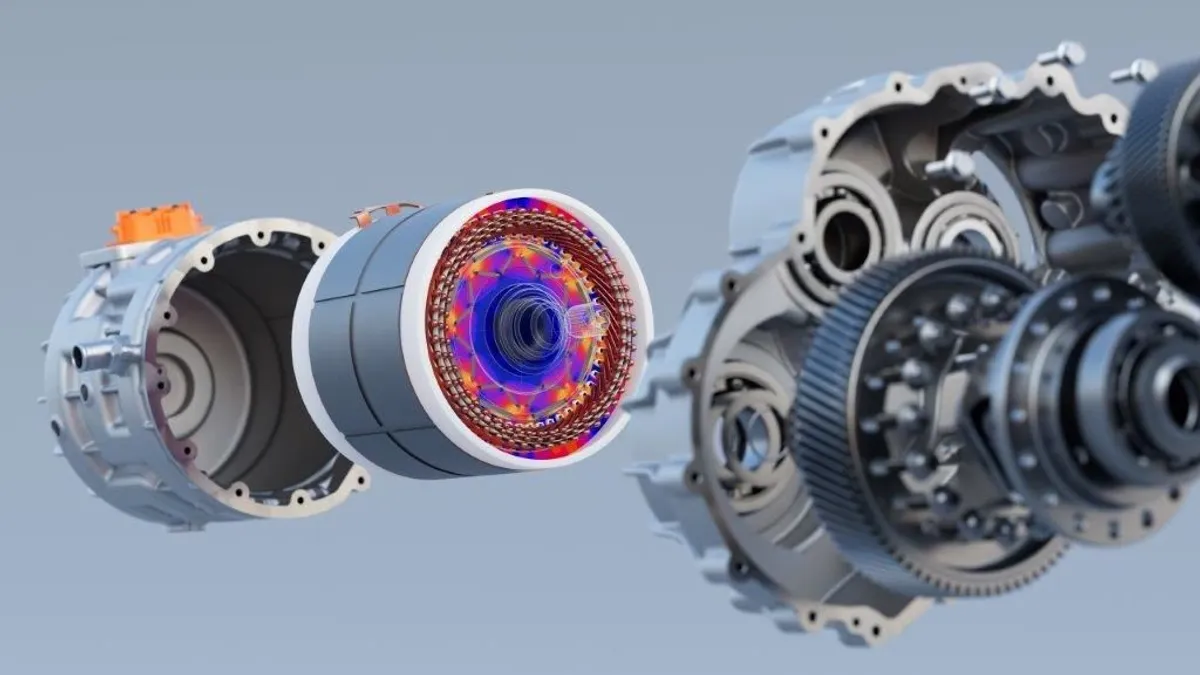

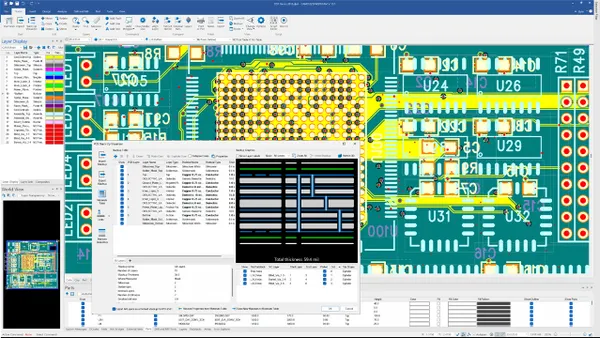

Some companies are already deploying the technology. Earlier this spring, auto manufacturer BMW started using industrial metaverse software created by Nvidia, called the Nvidia Omniverse. The omniverse combines Nvidia graphics, accelerated computing, simulation and AI technologies onto one platform, and will allow BMW to model logistics and robots at plants before they enter production.

“[The metaverse is] not very prevalent yet, but it certainly has vast potential,” said Lisa Anderson, president of LMA Consulting, a supply chain and manufacturing consultancy. “It has so many applications. I think we haven't even discovered or thought through all of the ways this can be utilized.”

Right now, one of the simplest applications of the technology is employee training. Surgeons already practice procedures using virtual reality, while firefighters rehearse navigating dangerous fires with the technology. Now, manufacturers are exploring using the same approach to prepare manufacturing employees for work on the shop floor.

“The metaverse — as people are popularly calling it — gives the ability to conduct training in sensitive environments in a manner that the people that are being trained are safe, as is the infrastructure,” explained David Crawley, a professor of practice at the University of Houston who has previously worked on industrial manufacturing projects.

Nokia, meanwhile, is working with firms, including the aircraft manufacturer Dassault, on industrial metaverse applications, including digital twin technology, the company said. The technology could also reduce the need for training equipment, said Tom Richter, the global head of discrete and process manufacturing verticals for digital industries at Nokia.

Virtual reality-based training may be especially appealing to younger people who are more familiar with using smartphones and virtual reality headsets, said Kevin Krot, head of mobility and industrial products at the operations and supply chain consulting firm SGS Maine Pointe.

“If you look at the manufacturing factories, they're having an aging issue right now,” Krot added. “Your workforce will need it because you won't have the 20 years of experience and you're going to have to train people up and this will be a way to increase their training and make the throughput efficiency and quality that is needed.”

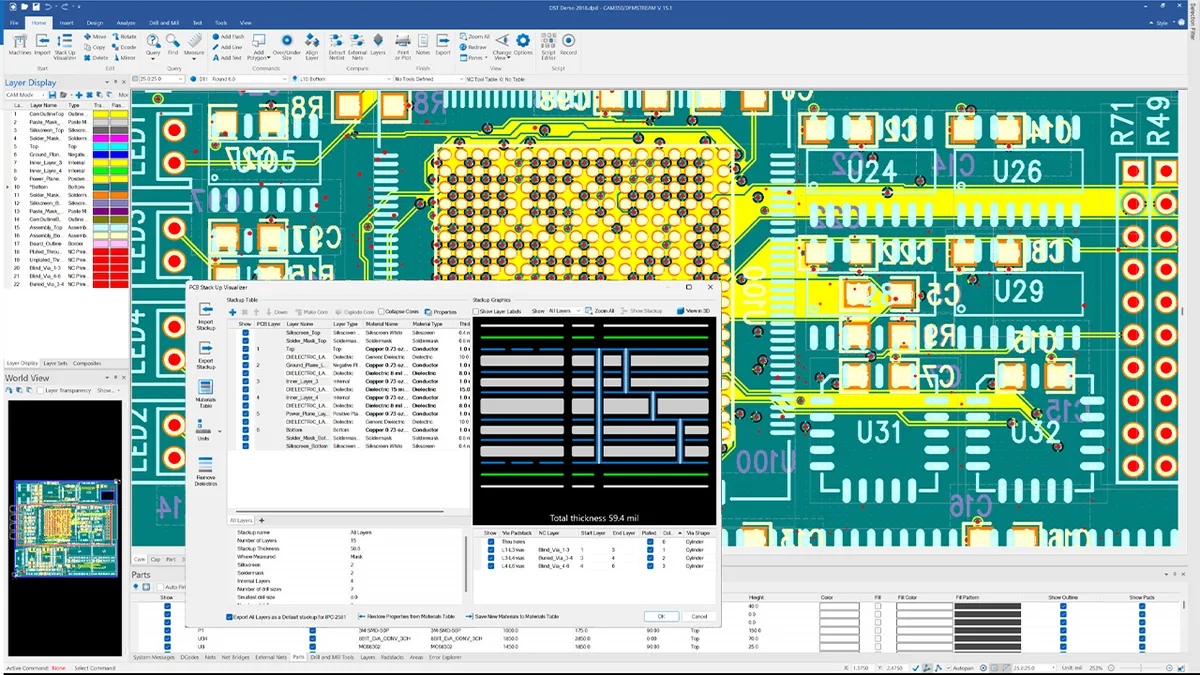

“The ability to virtualize more and more aspects of the physical world will in future not only allow for answers to rather simple questions like ‘does this size of the machine fit into this space’ based on a 3D-model, but to simulate the behavior of the complex environment of shopfloors or even full-scale plants."

Tom Richter

Global Head of Discrete and Process Manufacturing Verticals for Digital Industries, Nokia

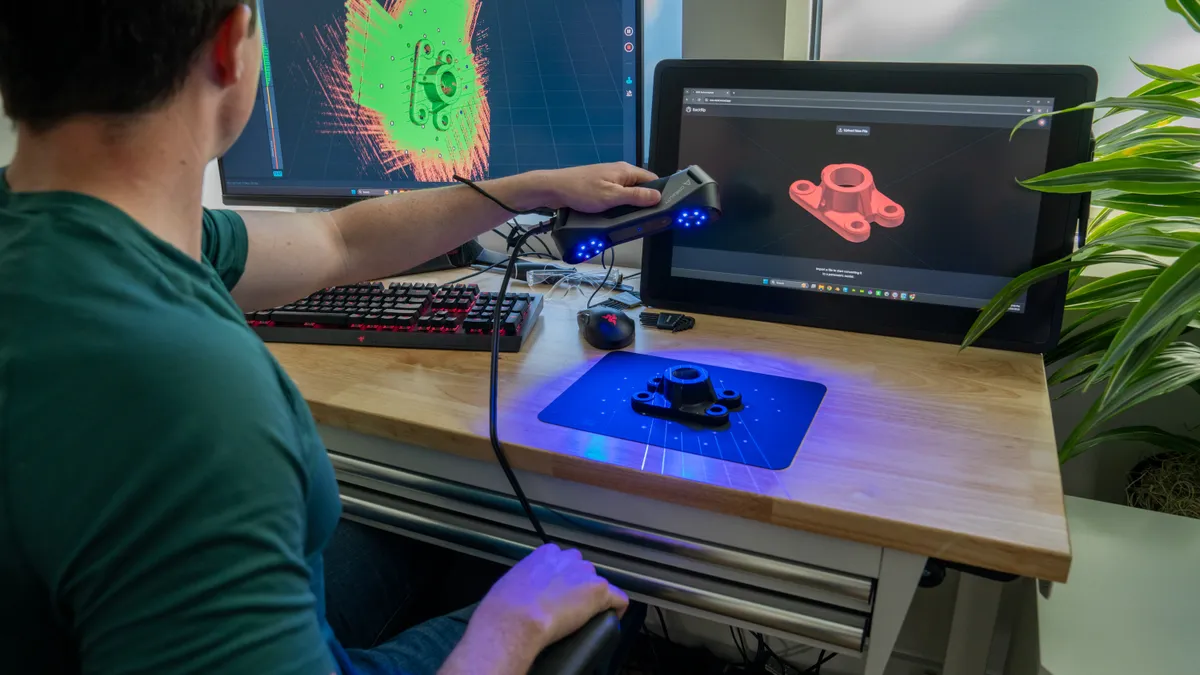

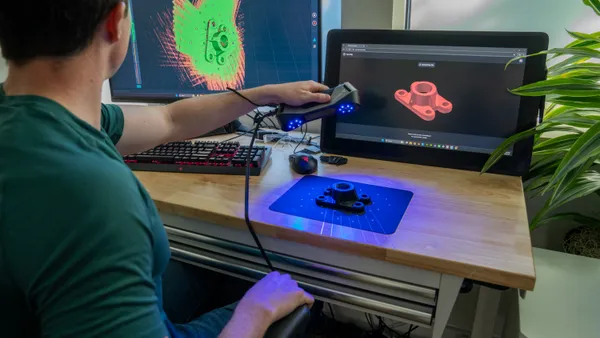

More ambitious uses of the technology could involve improving manufacturing operations, added Anderson, of LMA Consulting. Manufacturers can use the technology to model new products digitally, without, for example, having to waste materials.

The metaverse can also help with improving overall factory operations, including by allowing remote technicians to virtually explore problems and provide remotely provide guidance to equipment maintenance employees on the ground — which saves costs. In addition, the technology can help with exploring and optimizing different workflows, Richter said.

“The ability to virtualize more and more aspects of the physical world will in future not only allow for answers to rather simple questions like ‘does this size of the machine fit into this space’ based on a 3D-model, but to simulate the behavior of the complex environment of shopfloors or even full-scale plants,” he added.

Investing in metaverse technologies does come with caveats. The technology is costly and can require purchasing software and hardware, including sensors and headsets.

And while this technology can help companies save money as they attempt new innovations, many are also hesitant to invest in technology that’s “proactive,” rather than “reactive,” Krot said. Generally, industrial metaverse applications are still in their infancy, which means they may not be affordable or viable for many companies right now, even if they will be advantageous down the line.

Setting up one of these services can also require skilled technicians some manufacturing companies don’t necessarily have. In addition, these technologies might be harder to deploy if there’s a technology leadership gap, a problem many companies are facing amid labor constraints in the manufacturing industry.

Still, it’s possible that industrial metaverse applications could save manufacturers from making a range of expensive or time-intensive mistakes — by learning from them in the metaverse first.

“You have to have that commitment to have that long-term vision to make the capex change, sometimes it's going to be maybe a five-year or more payback,” added Krot. “When we get into a wave where there's more capital expenditures, larger programs that justify this, it will be the future.”