Mercedes-Benz is partnering with tech company NavVis to create digital twins of its manufacturing plants.

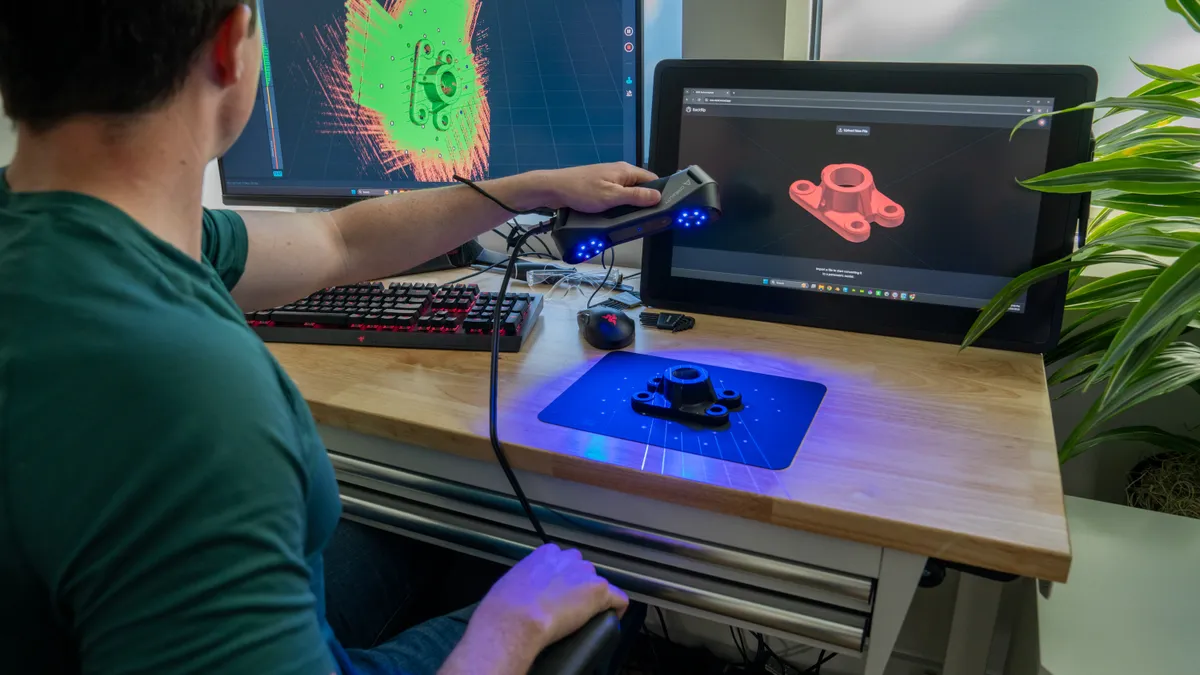

The cloud-based factory images and floor plans will allow the automaker to share information between planning, assembly or facility management teams to simulate production line changes or other process improvements, according to a press release.

The digital replicas allow Mercedes-Benz employees and partners to take measurements and mark important locations, acting as the "first touchpoint for all the people involved in factory planning," NavVis CEO and co-founder Felix Reinshagen said in a statement.

"We are constantly working on improving our production lines, but to do that you have to know what the plant currently looks like," Oliver Geissel, head of digitalization of production planning at Mercedes-Benz, said in the announcement.

"Now, our employees and partners can navigate through the virtual version of the plant and easily perform tasks such as simulating new layouts and optimizing available space from their devices — without ever stepping foot inside the actual plant,” Geissel said.

Founded in 2013, Germany-based NavVis operates in four countries, including Germany, the U.K., China and the U.S.

Mercedes-Benz is joining other automakers in using digital twins to enhance manufacturing operations.

Last year, BMW announced that it would create a digital twin of each of its plants worldwide, also partnering with NavVis to complete the digitization process.

Tesla, meanwhile, is known to create a digital twin of every car it manufactures. In addition, the EV maker has used digital twins to create digital models of power plants and model the recreation of the electrical grid in the age of alternative energy sources.