Editor’s note: This story is part of an ongoing series diving into the opportunities and challenges facing the manufacturing industry in 2023. Read the rest of the series here.

Manufacturers faced a variety of financial headwinds in 2022, ranging from elevated logistics costs to production disruptions as COVID-19 swept through China.

As companies continue to plan their budgets for the year ahead, many are looking at how to control their supply chain costs.

Resiliency is a common top priority as manufacturers aim to fortify their supply chains in the hopes of never again finding themselves caught off-guard by sudden global shifts.

In a year that already includes a volatile economy and geopolitical uncertainties, what supply chain costs should manufacturers be most concerned with and how can they mitigate them?

With prices stubbornly high, planning is a must

Manufacturers across the country are still contending with inflated material and labor costs, said Steve Young, a partner in Bain & Company's advanced manufacturing and services practice.

Attracting and maintaining a quality workforce ranked as the number one primary business challenge among more than 75% of respondents to the National Association of Manufacturers’ latest industry outlook survey. Supply chain challenges, increased raw material costs and transportation and logistics costs also ranked as significant issues.

The tension comes after years of push among manufacturers to meet demand spikes throughout the pandemic, regardless of budget, Young said. Now, companies are trying to get those costs back in line and focus on operational efficiency.

"Over the last several years, manufacturers and operations leaders have been under a lot of pressure to get output, and that output is at almost any cost, just to meet demand," Young said. “Places where in the past there were really tight controls on indirect spends, whether that be maintenance, engineering costs, [etc.], we're finding clients increasingly focused on getting control back on all those kinds of spends."

Supply chain issues top manufacturers' concerns

Having a thorough, up-to-date understanding of their company’s demand forecasts is one way a company can drive efficiency, according to Young. Operational and commercial teams should work closely together to understand what demand is coming, and how to align production and inventory accordingly.

"It's really important for the operations and the commercial teams and the strategy teams to work really closely together to get control of the underlying demand forecasts," he said. "We've gotten through periods where the demand trends in many industries have not been normal in a way that they have been in any recent history. Going back to the very basics of understanding the markets, the customers, the competition and where demand truly is going becomes really important."

With that, teams should also be in close communication with suppliers, both in a bid to control costs and understand where vulnerabilities in the supply chain lie.

"How do you think about two-way supplier communications? How do you think about supplier risk assessments?" Young said. "How do you think about putting strategies in place that create redundancies and resiliency in that supply base and can see risks out ahead and can address them before they become problems?

Supply chain resiliency may outweigh tight budgets

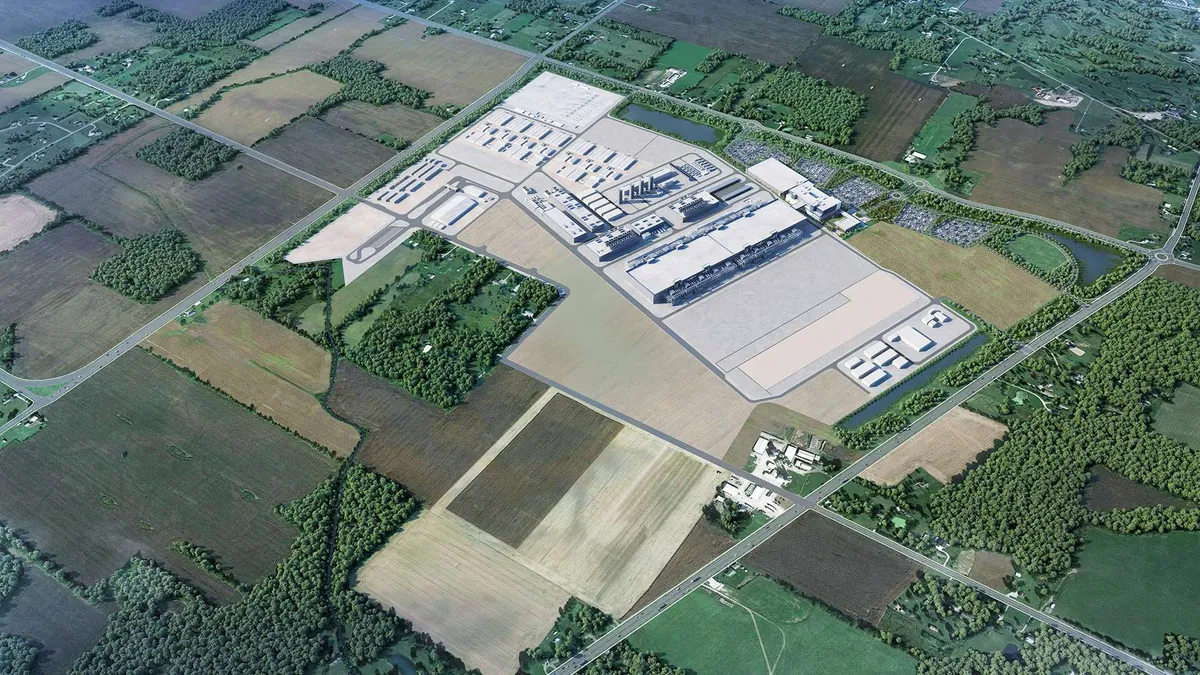

As manufacturers weigh how to safeguard their supply chains from future disruptions, one word has become particularly frequent — reshoring.

The trend of moving some or all of a company's supply chain closer to its home base has taken on greater importance in the wake of COVID-19-induced disruptions in manufacturing hubs like China.

"COVID challenged us to say how do we make our money, and is it all about low cost? Because if you're not on the shelf, all of that cost is lost quite quickly."

Cory Wendt

Principal, Baker Tilly

That trend is likely to accelerate in the year ahead, said Cory Wendt, a principal at Baker Tilly who focuses on manufacturing and distribution advisory.

“COVID challenged us to say how do we make our money, and is it all about low cost?” he said. “Because if you're not on the shelf, all of that cost is lost quite quickly."

Resiliency and domestic market opportunities are likely to outweigh a desire to cut costs, Wendt added.

While labor and other costs may be higher in the U.S. and nearby countries compared with places like China and Southeast Asia, reshoring offers other advantages, including less risk of supply chain disruption that can lead to lost revenue.

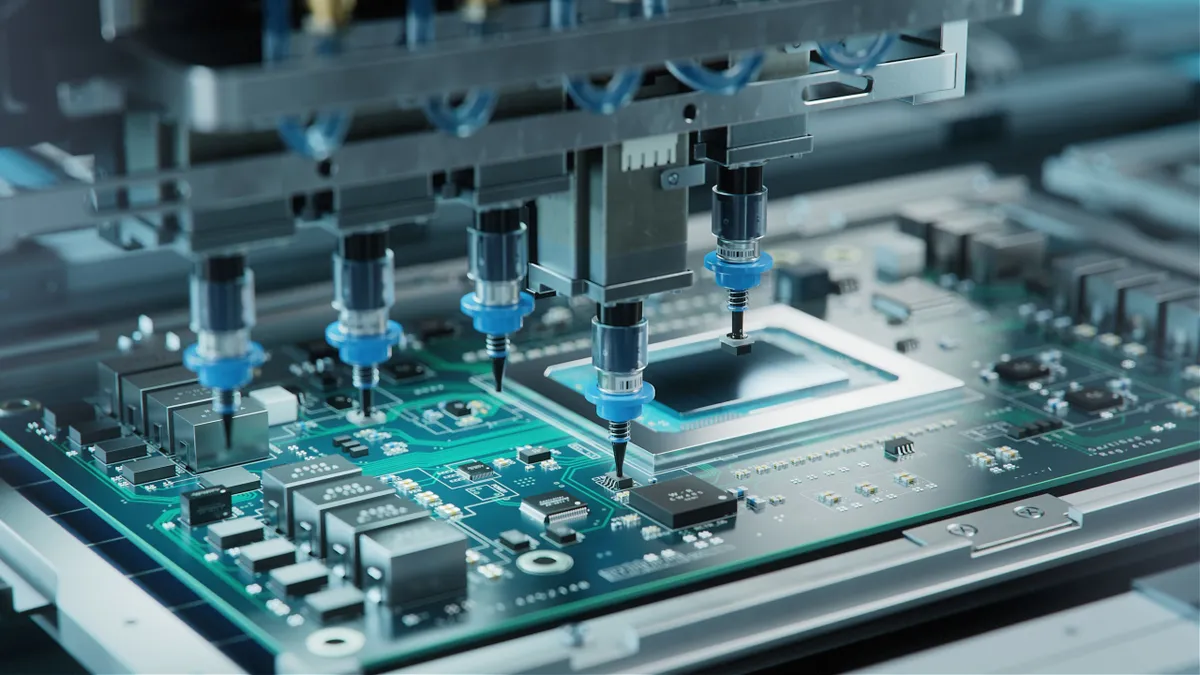

Auto and technology manufacturers in particular could relocate their supply chains to take advantage of tax credits offered by the Inflation Reduction Act. The law offers incentives for domestic production of key components, including critical minerals like those used in electric vehicles and EV batteries.

And with the EV market in the U.S. set to balloon in the coming year, the benefits of being close to the growing customer base are likely to be worth the extra costs.

"It's clear that that area is going to be a very strong growth sector," Wendt said. "And so those that get aligned with that quickly, it might be less about supply chain cost and more about being here and available.