As part of Ford Motor Co.’s new proposed four-and-a-half year labor contract with the United Auto Workers, the company is committing to $8.1 billion in manufacturing-related investments over the life of the agreement.

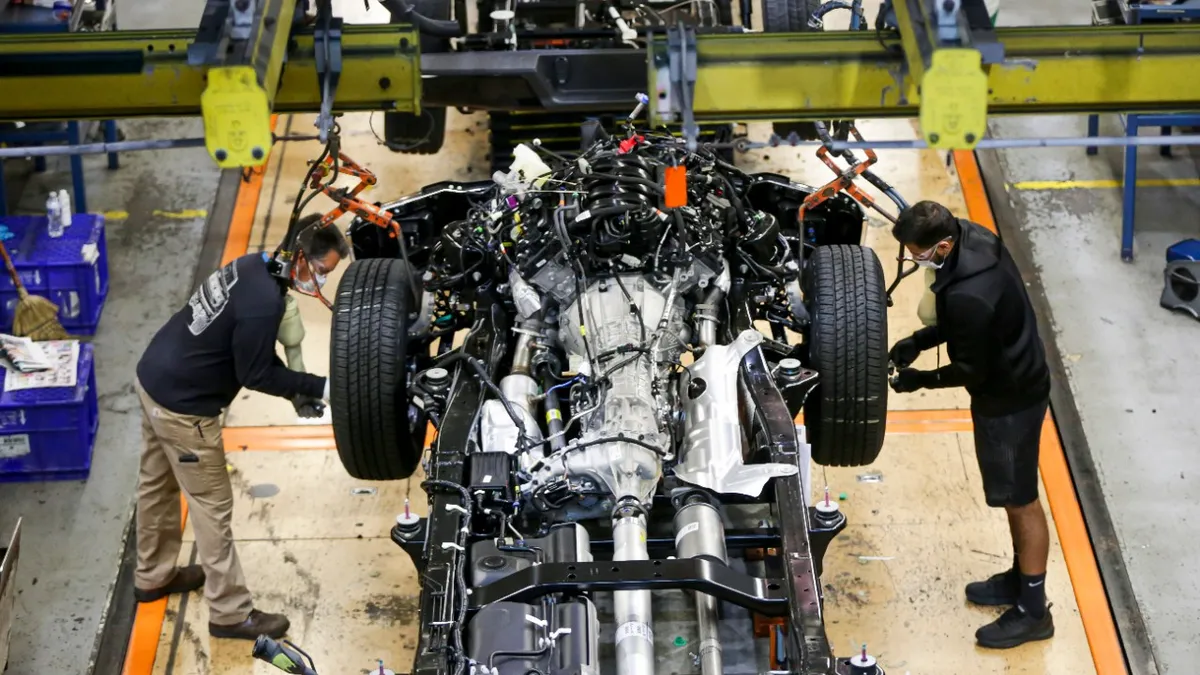

The money stretches across more than a dozen plants and includes the addition of new EV models, stamping improvements, added production crews and engine and transmission manufacturing investments.

"On product and investment, we won more than $8 billion in investments in our plants by the end of the agreement, from assembly to engine, from transmission and driveline to stamping," UAW VP Chuck Browning said during remarks on Saturday. "We have kept existing product in our plants and we have one new product that will keep members on the job."

Here's how Ford is investing across some of its biggest manufacturing plants.

Ford’s assembly plant investments

The automaker is also investing in its engine production facilities, including:

- $20 million at Dearborn Engine in Dearborn, Michigan;

- $100 million at Cleveland Engine in Cleveland, Ohio;

- $90 million at Lima Engine in Lima, Ohio; and

- $3 million at Woodhaven Forging in Woodhaven, Michigan.

On transmission and driveline manufacturing, the automaker is investing:

- $120 million at Livonia Transmission in Livonia, Michigan;

- $160 million at Sharonville Transmission in Sharonville, Ohio;

- $230 million at Van Dyke Electric Powertrain Center in Sterling Heights, Michigan;

- $200 million at Rawsonville Components in Ypsilanti, Michigan; and

- $130 million at Sterling Axle in Sterling Heights, Michigan.

Finally, on stamping processes, Ford is investing:

- $80 million at Buffalo Stamping in Buffalo, New York;

- $30 million at Chicago Stamping in Chicago, Illinois;

- $150 million at Dearborn Stamping and Dearborn Diversified Manufacturing in Dearborn, Michigan; and

- $150 million at Woodhaven Stamping in Woodhaven, Michigan.