Dive Brief:

- The Federal Aviation Administration is halting any request from Boeing for an expansion in production or approval of additional production lines of its Max jets, including the 737-9 Max, until quality control issues are resolved, the federal agency said on Wednesday.

- To ensure aircraft safety, the FAA approved a detailed set of inspection and maintenance processes after reviewing data from 40 grounded 737-9 Max aircraft. A Corrective Action Review Board comprised of safety experts also analyzed and approved the process.

- The FAA specified that the inspection and maintenance process must be performed on each of the 171 grounded Boeing 737-9 Max aircraft. Only after completion will the aircraft be able to return to service.

Dive Insight:

The FAA’s latest actions are part of its increased oversight of Boeing’s production and manufacturing processes after an Alaska Airlines-operated 737-9 Max plane door plug blew out midair while flying over Portland, Oregon, on Jan. 5.

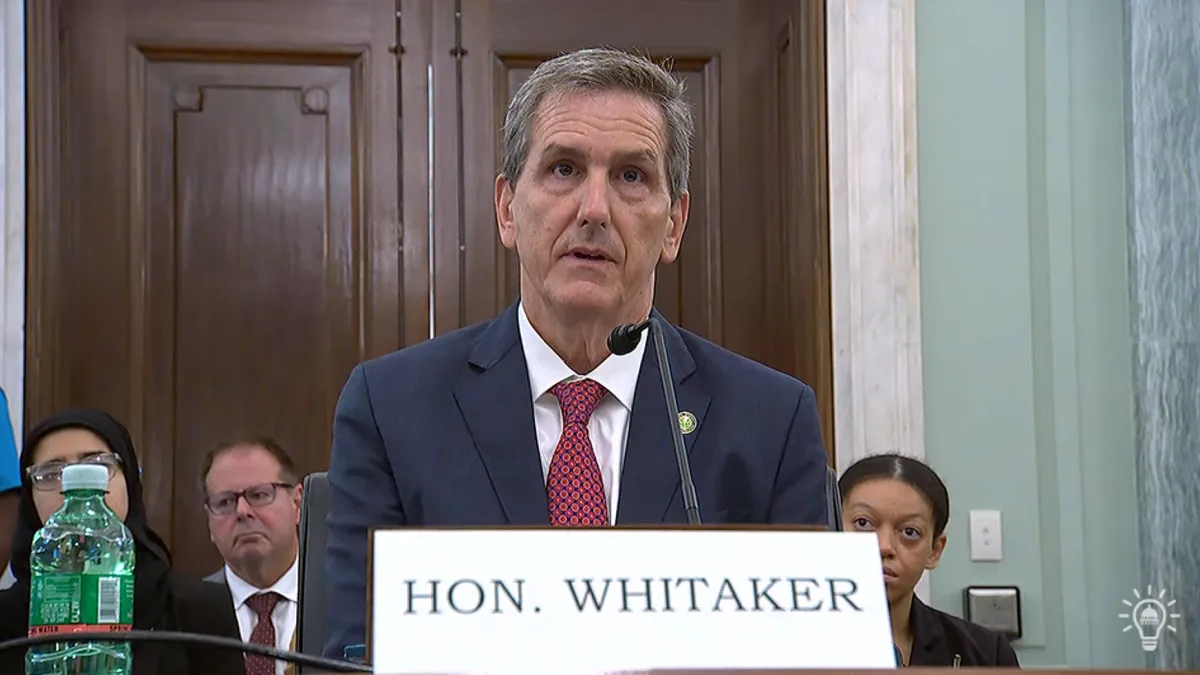

“We grounded the Boeing 737-9 MAX within hours of the incident over Portland and made clear this aircraft would not go back into service until it was safe,” FAA Administrator Mike Whitaker said in a statement.

The heightened maintenance process would include an inspection of specific bolts, guide tracks and fittings, detailed visual inspections of left and right mid-cabin exit door plugs and associated components, retorquing fasteners and correcting any other abnormal conditions.

Once the maintenance and inspection process on each aircraft is complete, the 737-9 Max’s door plugs will be in accordance with its original design. But that doesn’t mean it’s back to business for Boeing, according to Whitaker.

Due to “unacceptable” quality issues, the FAA plans to audit and monitor Boeing’s operational activities to address production quality concerns.

Increased oversight activities include:

- Capping expanded production of new Boeing 737 MAX aircraft to ensure accountability and full compliance with required quality control procedures.

- Launching an investigation scrutinizing Boeing’s compliance with manufacturing requirements. The FAA will use the full extent of its enforcement authority to ensure the company is held accountable for any non-compliance.

- Aggressively expanding oversight of new aircraft with increased floor presence at all Boeing facilities.

- Closely monitoring data to identify risk.

- Initiating an analysis of potential safety-focused reforms around quality control and delegation.

The FAA will continue to support the National Transportation Safety Board’s investigation into Alaska Airlines Flight 1282. The NTSB is in charge of the investigation and will provide any updates.

Boeing has been taking steps to resolve quality issues in its manufacturing processes. To help enforce quality assurance, the aerospace and defense contractor named retired Navy admiral Kirkland Donald on Jan. 16 as a special advisor to the company’s President and CEO Dave Calhoun.

Boeing’s 737 factory teams also held a “Quality Stand Down” in Renton, Washington, on Thursday. The Renton site paused two production shifts for the day so its 10,000 workers can participate in sessions focused on quality and safety. More stand downs are expected to be held at other commercial airplane sites in the coming weeks, the aircraft maker said.

“We will continue to cooperate fully and transparently with the FAA and follow their direction as we take action to strengthen safety and quality at Boeing,” Boeing said in a Jan. 24 statement. “We will also work closely with our airline customers as they complete the required inspection procedures to safely return their 737-9 airplanes to service.”