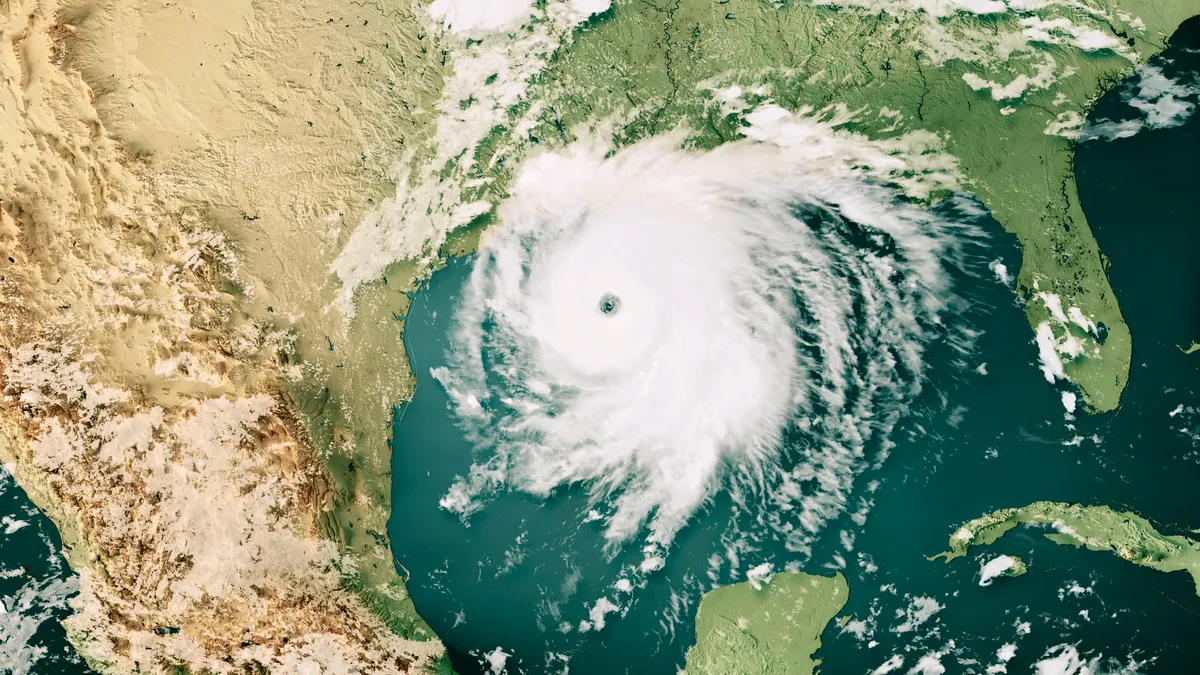

The U.S. Chemical Safety and Hazard Investigation Board is calling on chemical companies to prepare for hurricane season after National Oceanic and Atmospheric Administration scientists predicted a 60% chance of an above-normal Atlantic hurricane season.

Across the U.S., 746 chemical facilities are at risk of being affected by category 4 or 5 hurricanes, according to a Government Accountability Office report last year.

“Hurricanes and other extreme weather events can severely damage chemical facilities and cause chemical accidents that put nearby communities and facility workers in serious risk of harm,” CSB Chairperson Steve Owens said in a statement.

Chemical manufacturers should identify natural hazards that could occur at their facility and assess their risk level, such as by consulting the National Hurricane Center’s storm surge map, and create an emergency plan, according to the Center for Chemical Process Safety.

The CSB also called on the Federal Energy Regulatory Commission (FERC) — a federal agency that regulates the transmission of electricity, natural gas and oil — to take action and ensure electrical systems are protected from hurricanes and other high-wind extreme weather to prevent power losses at chemical facilities.

“With this hurricane season predicted to be even worse than usual, chemical companies need to act now to make sure that their facilities can withstand the impact of a hurricane or other extreme wind event, including having reliable back-up generators in case there is a loss of power to a facility,” Owens said.

Learning from the past

CSB cited two chemical facility incidents caused by hurricanes over the last six years as examples of what can happen if plants aren’t prepared for extreme weather.

In August 2017, residents near chemical manufacturer Arkema’s Crosby, Texas plant were evacuated for a week after Hurricane Harvey caused equipment flooding and failure in the facility. The failure caused chemicals to decompose and burn, as well as to release smoke and fumes, which exposed 21 people to the decomposing material fumes.

“It’s a reminder to all facilities, including chemical manufacturers, that they should prepare for these disasters that are becoming more intense and more frequent now.”

Alfredo Gómez

Director of Natural Resources and Environment at the U.S. Government Accountability Office

And during Hurricane Laura in August 2020, a fire broke out and damaged buildings storing trichloroisocyanuric acid, or chlorine used for pools and hot tubs, at water treatment product maker Bio-Lab’s facility in Westlake, Louisiana. The substance came into contact with water, resulting in a chemical reaction that caused the fire and decomposition of the substance.

The fire released large amounts of hazardous gases, shutting down a nearby highway for nearly 28 hours and prompting a shelter-in-place for nearby residents, as well as causing a power outage.

Bio-Lab invested $250 million to rebuild the facility, which reopened in November 2022.

“It’s a reminder to all facilities, including chemical manufacturers, that they should prepare for these disasters that are becoming more intense and more frequent now,” Alfredo Gómez, director of Natural Resources and Environment at the U.S. Government Accountability Office, told Manufacturing Dive.

Risk management plans

As the effects of climate change become more profound and impact industrial activities in the U.S., Gómez and the GAO are working to ensure companies consider these concerns when planning chemical operations and safety.

The office conducted a report last year that recommended the Environmental Protection Agency ensure facilities, including chemical manufacturers, consider risks from climate change.

Federal data found that roughly 31% of the 10,420 chemical facilities in the U.S. are located in areas affected by climate change’s heightened impact, such as through flooding, storm surges and rising sea levels.

Facilities that produce or handle hazardous chemicals are required to develop a risk management program to catch, prevent or minimize the outcome of an accidental release.

“So [chemical facilities] are looking for guidance to help them understand the risks that they’re facing from these natural hazards, which are being compounded by climate change,” Gómez said. “And then once they identify the risks, then how to manage the risks, what do they do about them.”

Gómez cited the example of materials manufacturer Covestro, which creates a response plan for its Baytown, Texas, facility before every hurricane season. The plan covers issues such as how the company will dispense resources for emergency response and ensuring trained staff are available during and after the storm to prevent chemical incidents.

“That’s an example of how a chemical manufacturer can make sure that their people are trained, that they’re working with first responders and that they really have thought about what are the risks that are facing them and what are their plans to deal with it,” Gómez said. “And it’s important because they have these hazardous chemicals that they’re producing, but that they’re also making sure that they’re safeguarded.”