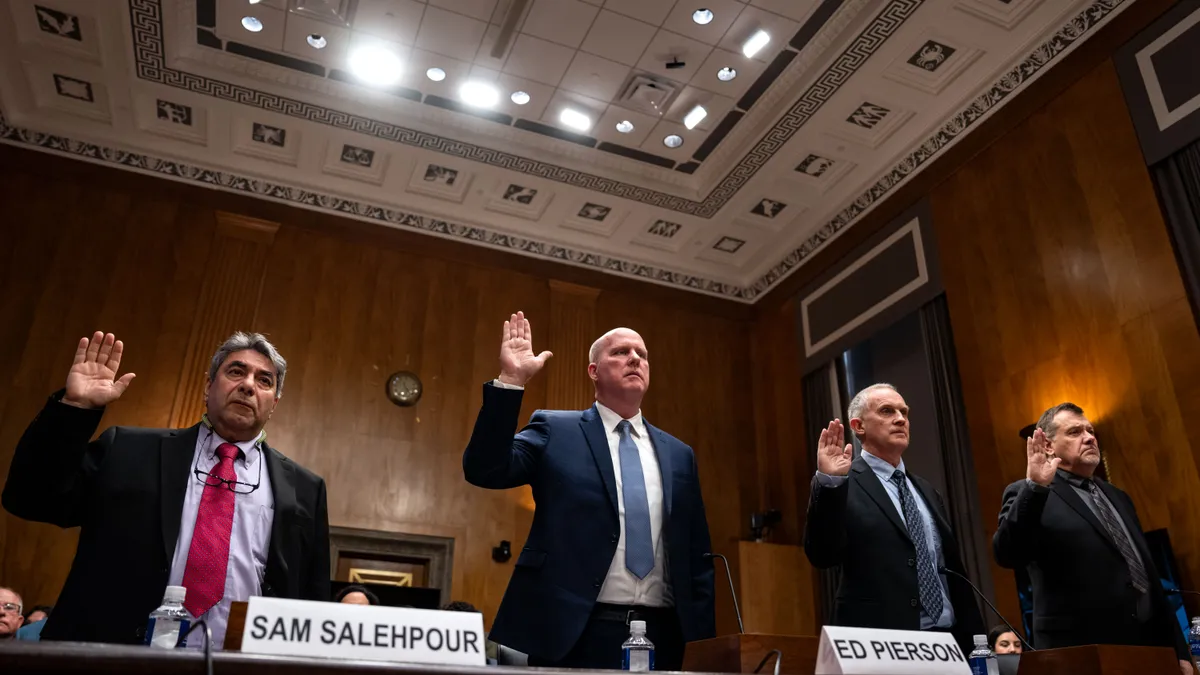

The National Transportation Safety Board grilled Boeing and fuselage manufacturer Spirit AeroSystems in a two-day set of hearings this week over the events leading up to January's Alaska Airlines 737-9 mid-exit door plug incident.

The hearings aimed to examine the manufacturing processes at the two companies' factories, and what safety lapses allowed for the improperly made door plug to get onto a runway.

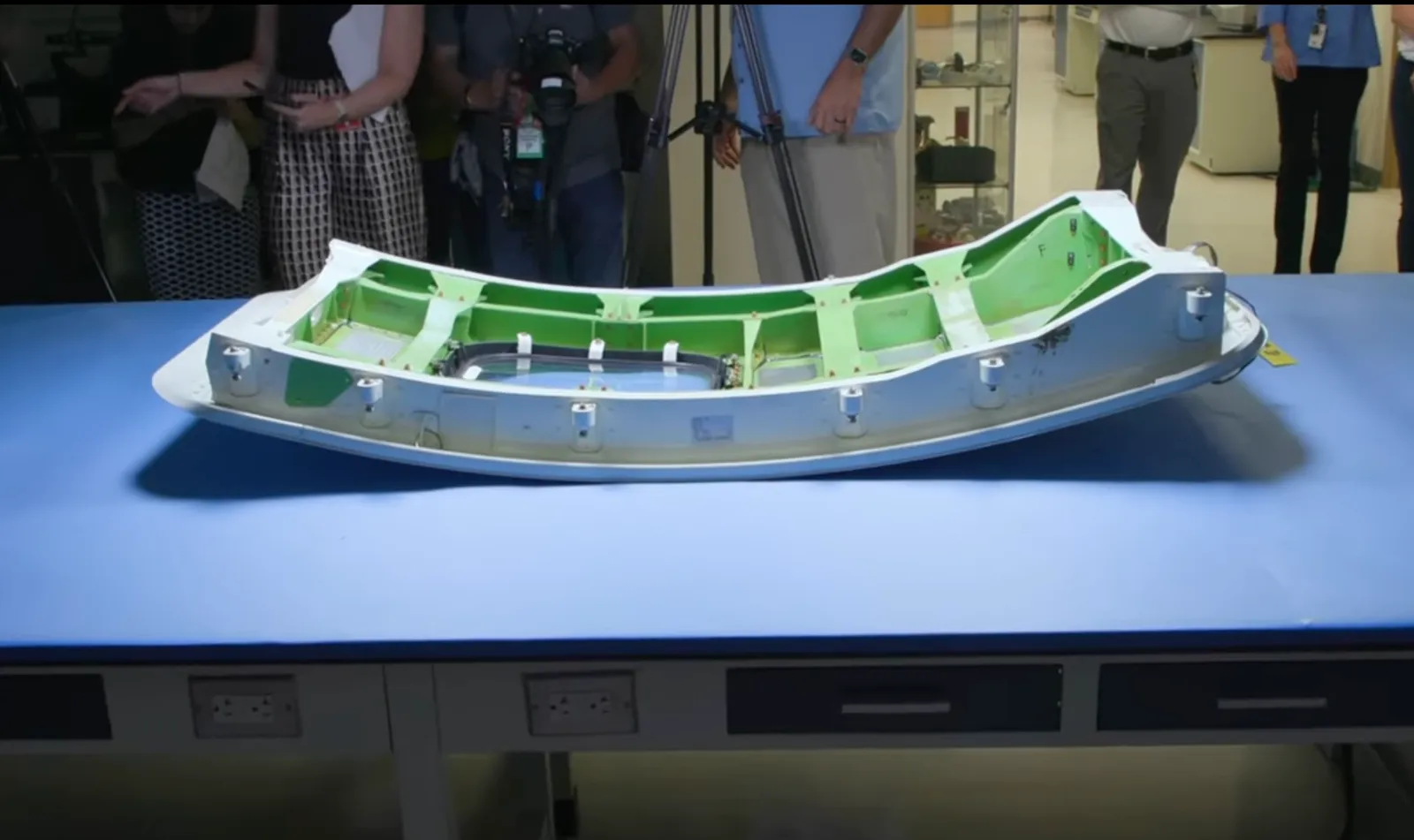

NTSB released its initial investigation in February, which revealed that four key bolts were missing from the plane, causing the mid-exit door plug to blow out. The bolts, which should have prevented the door from moving, were removed and seemingly not replaced during repairs at Boeing’s Renton, Washington, factory.

This week, the agency gathered more testimony and information about Boeing's state of operations, which will be used to complete its investigation and make safety recommendations.

While Boeing executives were required to appear as witnesses, Boeing was not allowed to ask other participants questions after the NTSB sanctioned the company for disclosing non-public and inaccurate information about the ongoing Alaska Airlines and Southwest investigations.

The hearings occurred in the two days before incoming CEO Kelly Ortberg took the helm at the planemaker on Aug. 8. Ortberg, who will be based in Seattle to be closer to Boeing's manufacturing operations, did not appear at the hearing.

‘The pressure does get heavy’

Interviews conducted before the hearing by NTSB with Boeing and Spirit AeroSystems workers and contractors revealed that they often work 10 to 12 hours, six to seven days a week, creating an environment of pressure and fatigue to meet demand.

The fuselage maker requests contractors be available either first or second shift, Monday through Friday, though voluntary overtime is available, Michael Riney, Boeing on-site customer relations director for Spirit Aerosystems at the Renton facility, said during testimony at the hearing.

For contractors however, it’s not overtime, it’s pressure to do work, NTSB Chair Jennifer Homendy said at the hearing, referring to the contractor interviews.

Employees also said they felt pressured by Boeing to get work completed quickly, noting "the pressure does get heavy." It could lead to workers skipping steps to get the job done, which has been identified as a risk, according to an NTSB interview with Elizabeth Lund, SVP of quality for Boeing Commercial Airplanes.

“One of the things we talk a lot about is, in aerospace, there’s sometimes is operational pressure,” Lund said during the hearing. “There’s operational pressure to release your airplane on time, there’s operational pressure for us to build and deliver the airplane. What can never happen, is to sacrifice quality or safety for operational pressure.”

‘Cockroaches of the factory’

Interviews conducted by NTSB revealed contract workers at the site described an us-versus-them situation between Boeing mechanics and subcontractors.

“Basically we’re the cockroaches of the factory,” one subcontractor said in an NTSB interview.

Riney noted that supplier contractors were outside workers, but did their best to stay out of Boeing mechanics' way.

“I think they just understand that their role is consistently between them and Boeing completing their work,” Riney said. “If I would have [heard concerns], I would've raised those to the Boeing team and I have no worry that it would have been addressed.

Design changes to prevent future incidents

Lund said during the hearing that Boeing engineers are working on design changes to prevent another door plug incident, which she expects will be implemented by year’s end.

The changes will prevent the door plugs from closing if there are any issues, notifying workers of movement, or if the door is not fully enclosed, Lund said.

NTSB's investigation is ongoing and will take up to 18 months to complete.