Dive Brief:

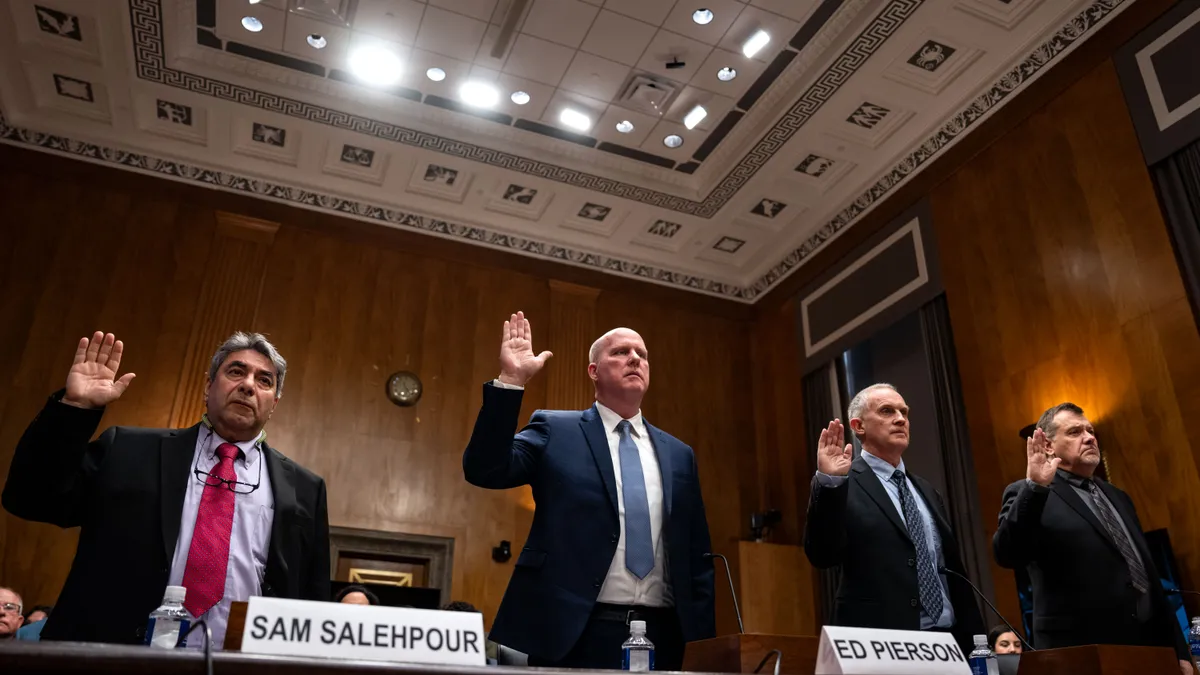

- Boeing released a safety and quality plan update last week for its manufacturing facilities, part of its strategy to improve safety in the wake of Alaska Airlines 737-9 Max plane door plug blowout in midair last year.

- Steps include new random quality audits of documented removals, increased product safety and quality training and added inspections at supplier Spirit AeroSystems assembly plants, according to an update from Boeing.

- The changes are part of Boeing’s safety improvement plan that it submitted to the Federal Aviation Administration in May 2024, with a proposal to address its systemic quality control and safety issues.

Dive Insight:

The safety and quality improvement plan focuses on four areas: elevating safety and quality culture, investing in workforce training, simplifying manufacturing processes and plans and eliminating defects.

The company submitted a safety improvement plan to the Federal Aviation Administration in May 2024 with a proposal to address its systemic quality control and safety issues. The agency paused Boeing’s expansion plans and capped its 737 Max production to 38 planes a month as the it evaluates the manufacturer’s progress on internal performance metrics.

“Boeing’s Safety & Quality Plan is on track with progress showing tangible improvements,” Boeing said in a handout sent to Manufacturing Dive Jan. 6. “Boeing will continue to implement improvements in each of the four focus areas in the new year.”

Although Boeing workers returned to work on Nov. 6 after a 53-day strike, the company took time to implement safety management systems, which are program-specific plans to identify, evaluate and mitigate potential manufacturing risks. Boeing resumed 737 Max production at its facilities in Renton and Everett, Washington, last month.

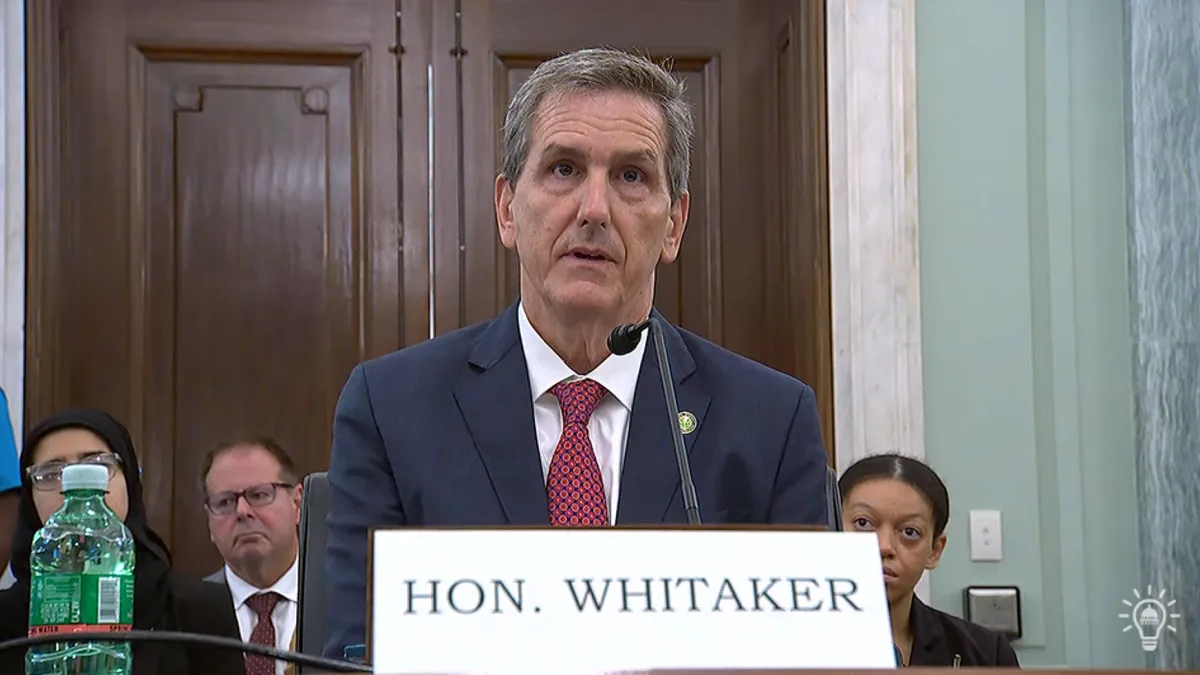

“As the strike ended, I spoke directly with the CEO [Kelly Ortberg] about the importance of adhering to safety-management principles as Boeing resumed production,” outgoing FAA Administrator Mike Whitaker said in the agency’s Jan. 3 blog post reflecting on the year since the Alaska Airlines incident. “It’s clear that message hit home, as Boeing spent a full month post-strike making sure the necessary safety steps were taken before restarting production.”

The company is progressing on its safety quality plan, Whitaker said. The agency is also consistently monitoring Boeing’s results as well as its key manufacturing plants.

The FAA has met with Boeing to review the manufacturer’s changes, progress and challenges as well as conduct surprise audits, Whitaker added.

“Our enhanced oversight is here to stay,” Whitaker said in the blog post. “But this is not a one-year project. What’s needed is a fundamental cultural shift at Boeing that’s oriented around safety and quality above profits. That will require sustained effort and commitment from Boeing, and unwavering scrutiny on our part.”