Boeing resumed 737 Max production at its facility in Renton, Washington, earlier this month, weeks after a 53-day workers’ strike forced a halt in factory operations, the company confirmed to Manufacturing Dive.

The aircraft maker declined to comment on when specifically it resumed production, but Reuters reported Boeing restarted 737 Max manufacturing on Dec. 6.

“Our team has worked methodically to restart factory operations in the Pacific Northwest,” the company said in a statement. “We have now resumed 737 production in our Renton factory, with our Everett programs on plan to follow in the days ahead.”

Although Boeing workers returned to work on Nov. 6, the company has been slow to resume full production as it implemented a safety management system to establish program-specific plans to identify, evaluate and mitigate potential manufacturing risks.

Prior to the strike, Boeing was on its way to achieving its goal of producing 38 planes a month by year’s end, a cap imposed by the Federal Aviation Administration, EVP and CFO Brian West said during a Q3 earnings call in October. That goal will now take longer to achieve due to the nearly two-month strike by the International Association of Machinists and Aerospace Workers.

We’ve restarted 737 production after weeks of methodical preparation to ensure our teams, parts and factories are ready.

— Boeing Airplanes (@BoeingAirplanes) December 10, 2024

Our production team loaded fresh 737 MAX fuselages into the Renton factory, and teammates who helped prepare the factory are in place to resume production. pic.twitter.com/U5vkBScP07

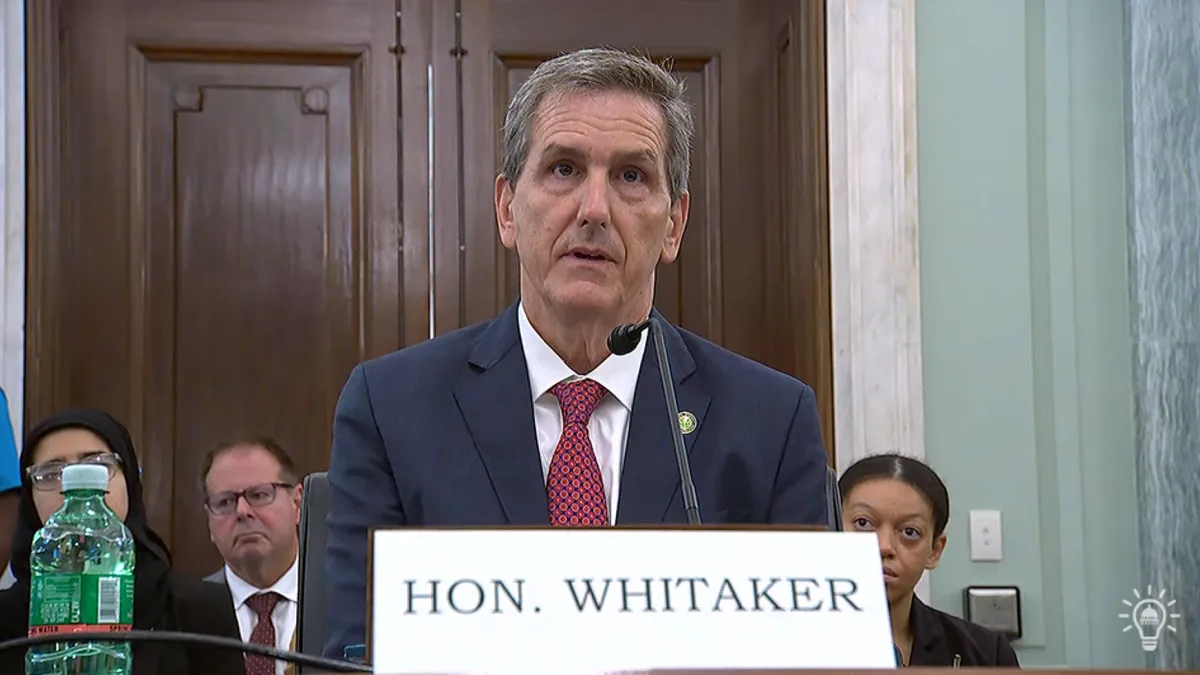

FAA Administrator Mike Whitaker visited Boeing’s Renton factory last week and met with frontline workers and CEO and President Kelly Ortberg, as well as observed how the company’s safety management system principles are guiding the manufacturer post-strike, according to the agency’s Dec. 5 statement. This included Boeing’s new technology deployments and expanded employee training programs.

“Over the last several weeks, we dedicated time toward training and certification, ensuring parts and tools are ready, and completing work on airplanes in inventory to prepare for the resumption of production at pre-work stoppage levels,” Boeing said in a statement.

Boeing’s safety management system plan is part of the FAA’s increased oversight of Boeing’s production process after an Alaska Airlines 737-9 Max plane door plug blew out midair in January. Whitaker’s Renton factory visit is part of the agency’s commitment to ensure the aircraft maker corrects its systemic quality-control issues, according to the FAA statement.

“What’s truly needed is a fundamental cultural shift that’s oriented around safety, quality improvement and effective employee engagement and training,” Whitaker said in the statement. “As expected, Boeing has made progress executing its comprehensive plan in these areas, and we will continue to closely monitor the results as they begin to ramp up production following the strike.”