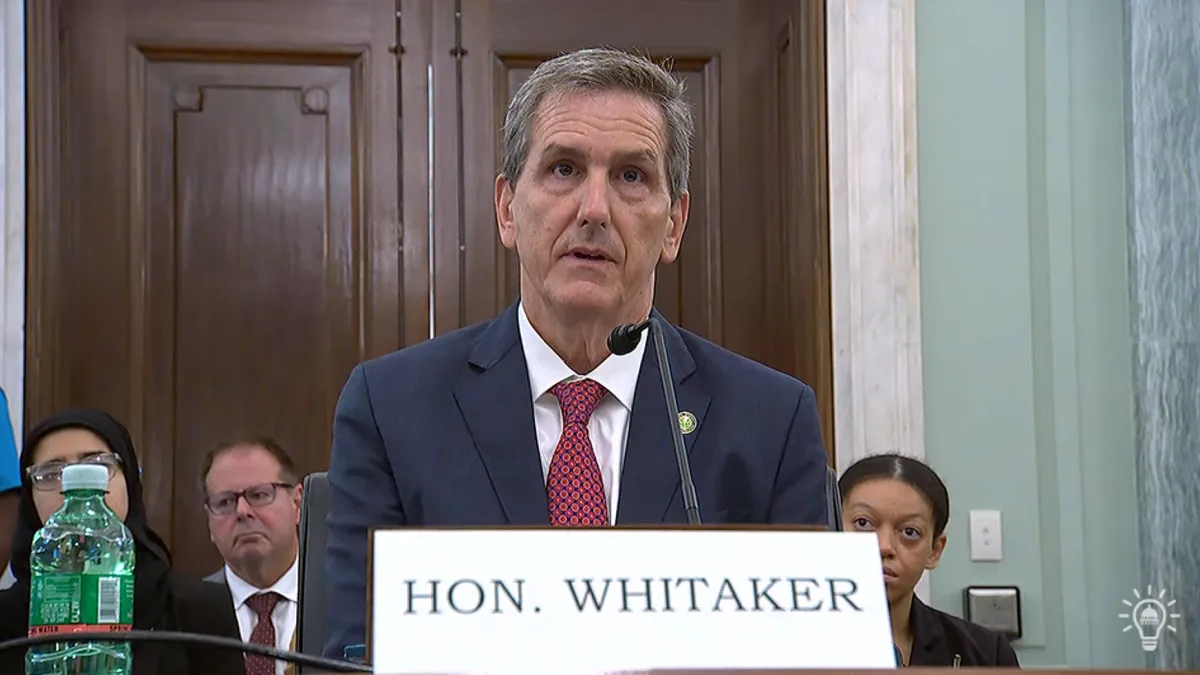

The Federal Aviation Administration should have kept closer oversight of Boeing before the January Alaska Airlines door plug incident, FAA Administrator Michael Whitaker told lawmakers at a Senate Committee on Commerce, Science and Transportation hearing on Thursday.

“FAA’s approach was too hands-off, too focused on paperwork audits and not focused enough on inspection,” Whitaker said in his testimony. “We have changed that approach over the last several months, and those changes are permanent.”

The Senate hearing came two weeks after Boeing submitted its safety improvement plan to the FAA with a proposal to address its systemic quality control and safety issues. The FAA will continue to exercise heightened oversight of the aircraft maker, including adding more safety inspectors at Boeing and supplier Spirit AeroSystems’ production facilities and doing further evaluations of the manufacturing process, Whitaker told senators.

“We anticipate that Boeing’s roadmap will be part of an iterative process as it receives feedback and implement improvements to their design, manufacturing, and production processes,” Whitaker said in his testimony.

FAA wants to bring on more inspectors for Boeing

As part of its increased oversight of Boeing's production process, Whitaker noted that the agency needs to increase the number of inspectors who conduct audits, speak with employees and verify work is completed correctly, from about three dozen to 55 inspectors. Inspectors work at both Boeing’s Renton, Washington, factory and Spirit AeroSystems’ Wichita, Kansas, plant.

“That's our best estimate at this point, based on where we think we need to deploy them,” Whitaker said. “A key to how we want to do oversight going forward is to have flexibility to make sure we're putting our assets where they need to be.”

The increased number of inspectors on site allows the FAA to learn what the companies’ staff needs and receive continuous feedback, as well as manage the manufacturer's tools, parts and technologies.

“Once we see that successful, we won’t need as many inspectors there,” Whitaker said. “They might be redeployed to some other aspect of production. So it's designed to be a flexible system based on feedback.”

The FAA will monitor the aircraft maker’s internal KPIs, as well as its own performance metrics, to evaluate the overall health of Boeing's production and quality systems before allowing the company to increase its production.

The agency is maintaining its 38-unit monthly production cap on Boeing’s 737 program until those performance metrics can still be met even if the company increases capacity, Whitaker said. The aircraft maker’s production plans have been on pause since late January.

Those metrics are currently being implemented, Whitaker said. The agency is establishing what it called “green, yellow and red zones” for production, and Boeing will need to stay in the green while ramping manufacturing again.

“We'll be able to watch that as they start to increase production from the current level and make an evaluation as they get to that purview,” the FAA administrator said.