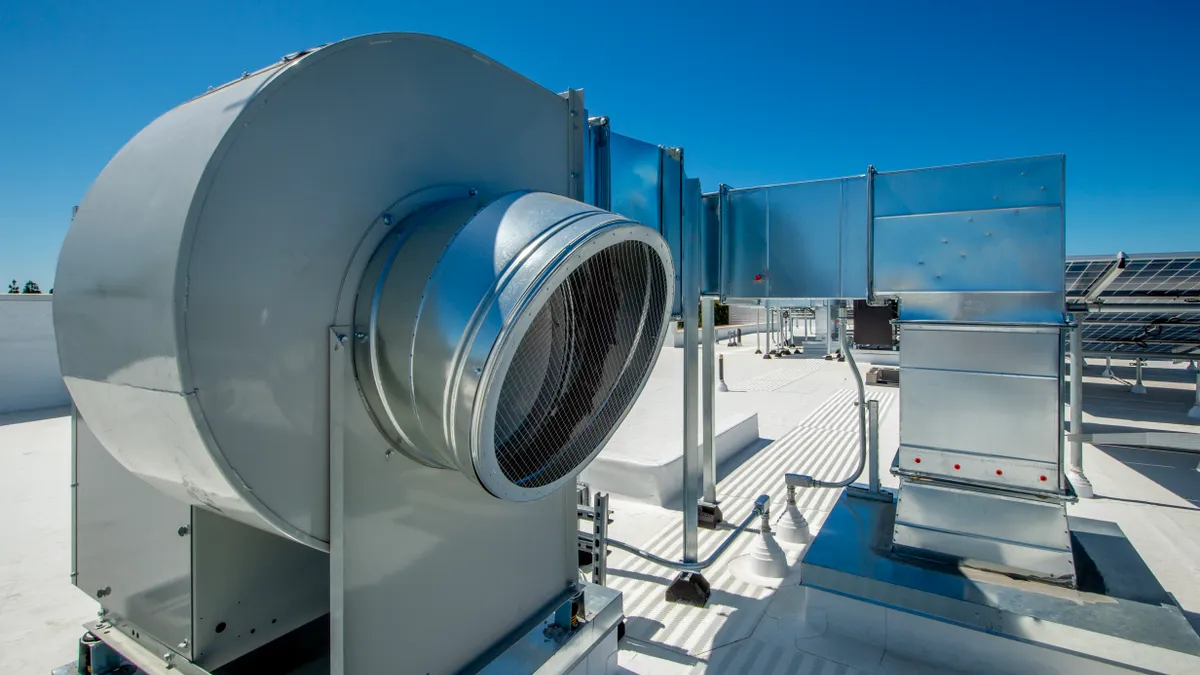

The Biden administration is investing $35 million in domestic production of sterile injectable medicines in an effort to combat the country's ongoing drug shortage.

The move is part of a slate of actions taken by the White House late last month to strengthen the country's supply chains. It includes broadening the Defense Production Act to spur domestic drug manufacturing of essential medicines, according to a Nov. 27 White House fact sheet.

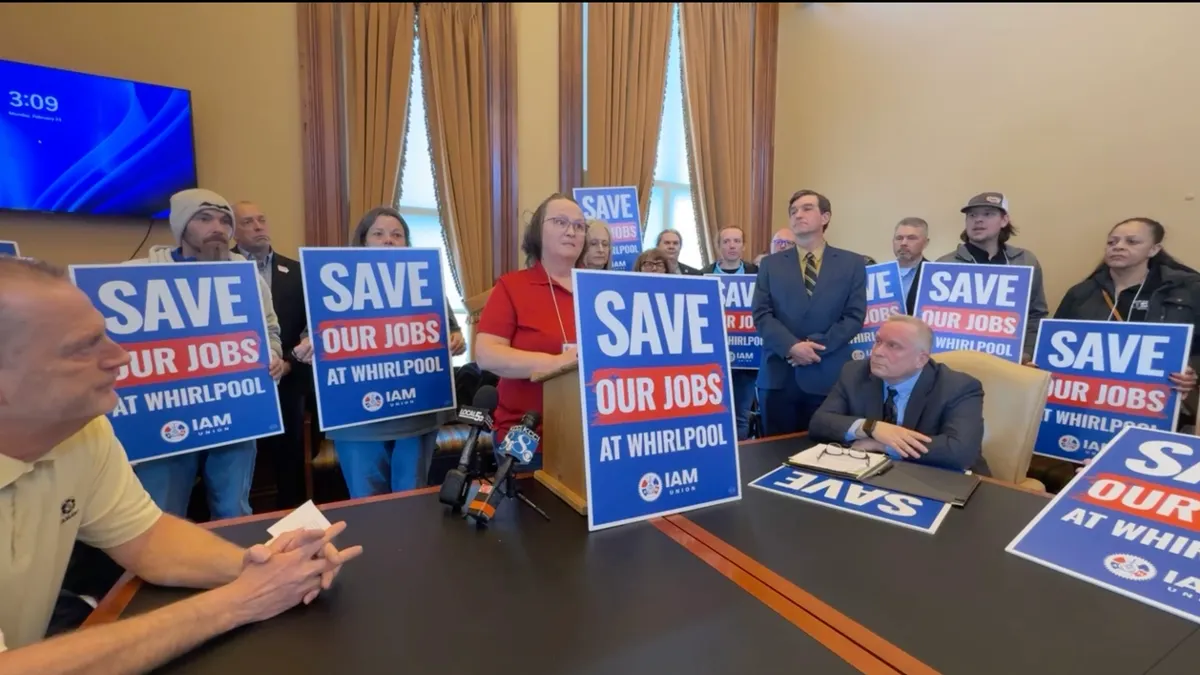

The measure comes at a time when shortages are rising in many different drug categories, including chemotherapy and hormonal medicines, oral liquids like amoxicillin, and prefilled syringes, according to a July 2023 American Society of Health-System Pharmacists drug shortages survey.

There were 309 active, ongoing drug shortages in June and July, the highest number in nearly a decade and close to the all-time high of 320 shortages, according to the survey.

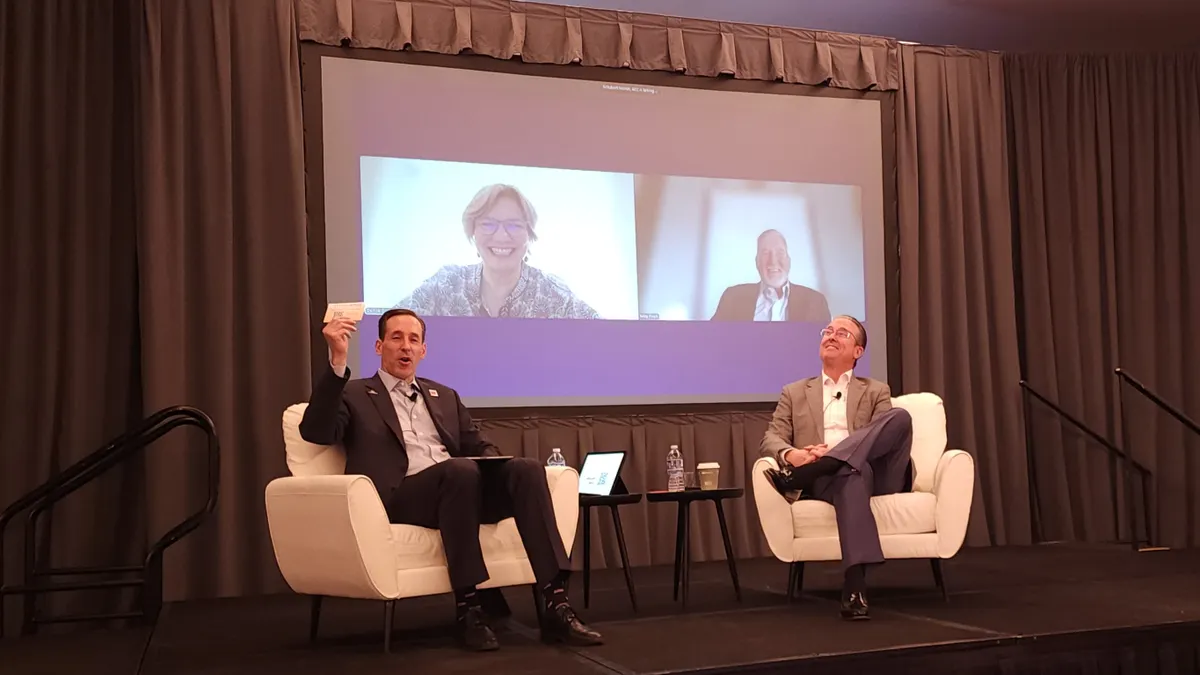

Most of the shortages are affecting generic drugs, according to Douglas Hoey, CEO of the National Community Pharmacists Association.

How the public and private sector should tackle the shortage is up for debate, with some stakeholders pushing for a greater diversity of suppliers and manufacturers, while others say it comes down to drug pricing.

The government has said the geographic concentration of raw drug ingredients in countries such as China and India creates a risk in transparency and quality control for U.S. drug manufacturers, according to a March report from the Senate Homeland Security and Governmental Affairs committee.

The Administration for Strategic Preparedness and Response estimates that 90% to 95% of generic sterile injectable drugs used for critical acute care in the U.S. rely on key starting materials from China and India, the report states.

The Biden administration has pushed to fund an increase in domestic manufacturing as a way to combat supply chain issues in pharmaceuticals, with measures taken in 2021 as well as those last month to encourage more production capacity.

Yet some experts say expanding domestic drug production capacity is not the only strategy that needs to be explored to tackle drug shortages.

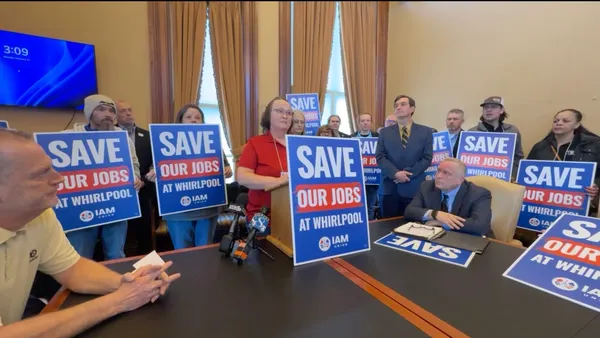

Hoey said the drug manufacturing and supply chain issues have much to do with pharmacy benefit managers and lack of transparency in the overall system from the production of drugs to their final destination on patients’ doorsteps.

Today, the three largest pharmacy benefit managers, CVS Caremarks, Express Scripts and OptumRx control approximately 89% of the market, serving about 270 million Americans, according to the National Association of Insurance Commissioners.

“Their buying power, their market influence is so large, that from a manufacturer standpoint, they can dictate terms,” Hoey said. “They can say, you will sell me your drug at this price or we just won't carry you.”

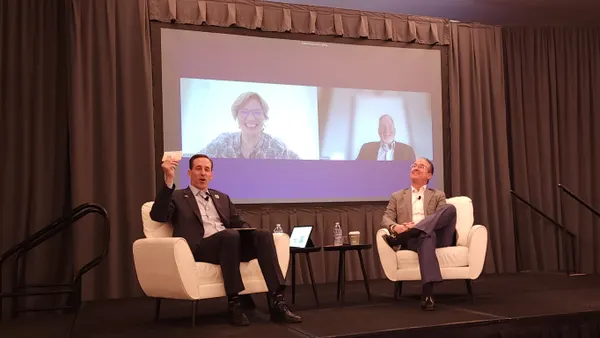

“To be honest, as purchasers of these pharmaceuticals, we have no idea to what extent we're relying on other countries or, more specifically, no matter what country [it] is, how many suppliers are there? How resilient or robust is the supply chain?”

Michael Ganio

Senior Director, Pharmacy Practice and Quality, American Society of Health-System Pharmacists

Michael Ganio, senior director of pharmacy practice and quality at the American Society of Health-System Pharmacists, agreed that transparency is a root cause to the U.S.'s drug manufacturing problem, and that onshoring operations isn’t necessarily the solution. He pointed to multiple examples of drug shortages in recent years that have involved medicines produced in the U.S., such as a saline injectable shortage in 2017 and a shortage of injectable opioid drugs in 2018.

“To be honest, as purchasers of these pharmaceuticals, we have no idea to what extent we're relying on other countries or, more specifically, no matter what country [it] is, how many suppliers are there? How resilient or robust is the supply chain?” Ganio said.

While the Biden administration's $35 million for manufacturing is a hopeful start to fortify the U.S. drug supply chain, Hoey said it’s going to take a lot more investment and policy shifts regarding how prescription drugs are paid for in the U.S.

“It's going to take an overhaul of how drugs are paid for by our government,” Hoey said. “Right now, there's an incentive to drive the cost down so low that it's no longer as profitable for a manufacturer to make the drug. Yet the government is still paying the higher price because this [pharmacy benefit manager] is in the middle. It charges them a higher price than what they actually pay the pharmacy.”

With sterile injectables specifically, the focus of the Biden administration’s recent funding, Hoey said there are a limited number of manufacturers that can comply with the rigorous sterility requirements in the U.S. Normal saline for example, which is used in millions of procedures every week, is a sterile injectable that should always be in supply.

“If one of those suppliers shuts down or stops providing drugs, it creates a ripple effect throughout the entire medical community. And so, we need to make sure that we have a robust supply of that,” Hoey said.

When it comes to generic drugs that face fewer production restrictions, Hoey noted it's a matter of supply and demand.

“On occasion, it's raw supply, where the drug is just hard to get by, or it's in hyper demand, like the GLP-1’s right now. They're on the shortage list because they're just in hyper demand. But more often than not, it’s an economic issue where the market either is no longer profitable to continue to make the drugs or the number of suppliers has been narrowed down so so tight,” Hoey said.

Moving forward, the Department of Health and Human Services will appoint a supply chain resilience and shortage coordinator to spearhead strengthening critical medical product and food supply chains and related shortages.

The Department of Commerce and the Administration for Strategic Preparedness and Response are also teaming up to identify and fix points of failure in the U.S. public health industrial base supply chain, prioritizing supplies for the production of the influenza vaccine, FDA-designated essential medicines, and high-impact biological medical countermeasures, according to the Department of Health and Human Service.