The global additive manufacturing industry was valued at over $20 billion in 2023.

Additive manufacturing is slated to grow rapidly as companies use AI to experiment with designs, make the production process more efficient, increase accuracy and streamline supply chains. From initial design and simulation to real-time quality control, AI is boosting productivity and profitability, fueling innovation and addressing critical skills shortages in the manufacturing sector.

Using AI in additive manufacturing

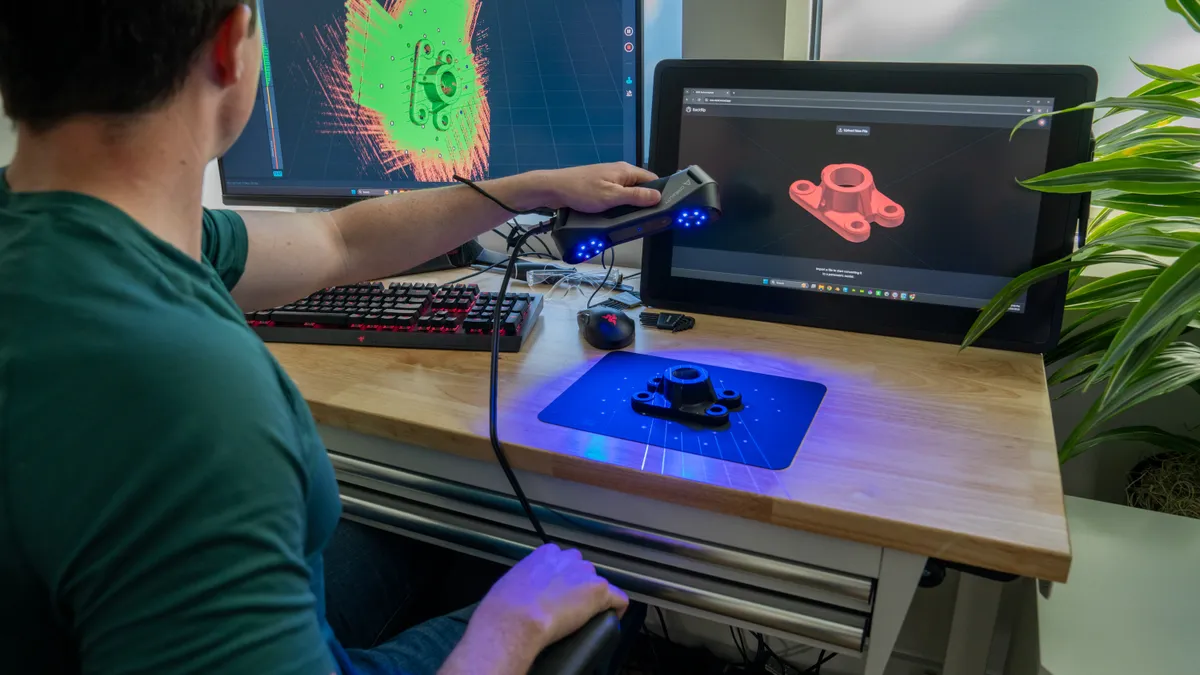

The additive manufacturing process goes through various stages, including part design, the creation of machine instructions for printing, process parameter development and testing of the manufactured part, said Nikhil Gupta, a mechanical and aerospace engineering professor at New York University.

Companies are now embedding AI into each step of this process. Generative AI algorithms can design components that are up to 30% to 70% lighter than traditionally produced parts, without compromising strength. Optical and thermal cameras integrated into industrial 3D printers can also capture real-time data used to analyze and detect quality discrepancies as they occur, Gupta added.

This has revolutionized additive manufacturing by making tasks that were once nearly impossible due to their time and resource intensity much more feasible and cost-effective through AI.

For instance, most industrial-grade 3D printers have cameras that capture each layer of a part as it is being printed. Complex parts print in thousands of layers over a period of days, which makes manual, real-time human inspection for defects or anomalies neither possible nor cost efficient, Gupta said.

“AI algorithms are being trained to automatically detect anomalies in the print layer and flag them for further inspection,” he added. “Detection of a defect as it originates provides the possibility to intervene to fix it and not waste the time and material already spent.”

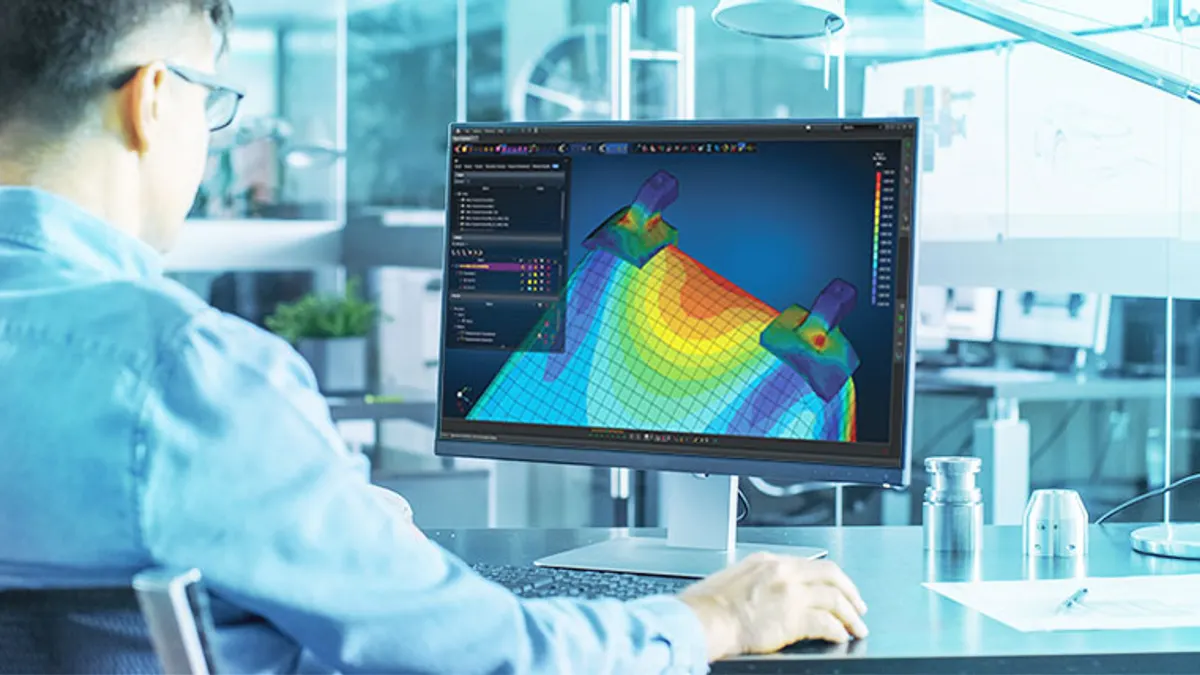

AI can optimize the process by analyzing real-time sensor data and make changes before going into production. This can help ensure parts meet exact specifications, a capability crucial for high-precision industries such as medical devices and aerospace, said Robbie Long, product marketing manager at Fictiv.

Fictiv has developed a Materials.AI assistant, which is integrated into the company’s digital manufacturing platform and allows engineers to compare material options best suited for their production needs. Powered by ChatGPT, the tool lets manufacturers ask questions about which materials or processes they should use for their 3D printing product, Long said.

For example, manufacturers can compare the most heat-resistance or cost-effective materials and make informed decisions without spending a fortune on trial and error.

Scenario planning and tool clearances

In addition to design, production, and quality control, manufacturers are implementing AI for more complex processes, pushing the boundaries of what has been possible so far.

“Manufacturers can run their plant data in an AI model for scenario planning – giving them the ability to test multiple functions of additive manufacturing in a digital environment before investing in the real thing,” said Tim Gaus, smart manufacturing business leader at Deloitte. It can function like a digital twin for rapid prototyping and simulations.

Another application is agentic AI for tool clearances. Tool clearances require manufacturers to ensure that the space for tools is included in their computer-aided design when going from digital to physical product iterations, Gaus said.

“To save manufacturers the time of manually undergoing this process, some have created AI agents that review the CAD model and assess whether the included tooling clearances are sufficient," Gaus added. The AI agent will flag if it detects an issue with the clearances and recommends solutions to remedy the problem.

A key area enhanced by AI is maintenance.

“AI models can be trained on the machine’s manuals, historical and current operational data, and failure codes to provide maintenance crews with recommendations on how to fix potential problems, ultimately taking on the responsibility of maintaining these,” Gaus said.

Using AI in additive manufacturing also accelerates the jobs of product and industrial engineers by decreasing the time it takes to design and run a product, Gaus added.

“It allows for more flexible, on-demand production, meaning workers can avoid burning time on large-scale repetitive tasks and instead focus on more customized production runs," he said.

Lowering barriers to entry

Because integrating AI in additive manufacturing simplifies otherwise complex tasks, it has opened the door for workers at all levels to participate in the process. Companies like Backflip AI have built tools that let someone take an idea — a drawing, sketch, photo or text — and in one click turn it into a highly detailed 3D model that can then be manufactured.

“That’s huge because it means people who have never touched a traditional 3D design tool can produce real parts from a simple text description, or even by snapping a photo of something that broke and needs to be replaced,” said Greg Mark, CEO and co-founder of the company. “This reduces the barrier for entry into the field and enables the folks who are already in the industry to increase their productivity."

The company’s AI-powered design platform has been used by large toy manufacturers, CPG companies, interior designers, and even for costumes and SFX in Hollywood. This is useful when clients come in without a clear idea of what they want designed, Mark said.

“Using AI allows these companies to quickly workshop different ideas without spending a ton of time, money, and energy fine-tuning each concept during the ideation stage.