Machinery and materials maker Kennametal will close three to five plants over the next four years to reduce structural costs, CFO and VP Patrick Watson said at the company’s Investor Day earlier this month.

The move is part of a $100 million cost-savings push, which includes $20 million from a restructuring program the company announced in June. The initiative is intended to streamline Kennametal’s cost structure while it continues investing in high-return commercial and operational initiatives over the next four years.

In the two years after Kennametal announced restructuring plans in 2019, it closed six plants worldwide, including sites in Irwin, Pennsylvania, and Johnson City, Tennessee.

The latest restructuring and plant closures are part of Kennametal’s next phase, President and CEO Christopher Rossi told investors.

“In this version here, we’ve got another three to five opportunities,” Rossi said. “But the way manufacturing works, and this mentality around continuous improvement, we’ll continue to always look to optimize that footprint.”

The company plans to reduce costs by optimizing its inventory levels, improving its customer service and working on ongoing improvement projects, Watson said. Kennametal will also work on reducing tungsten costs by improving its recycling abilities and processes, which would save the company about 1% annually.

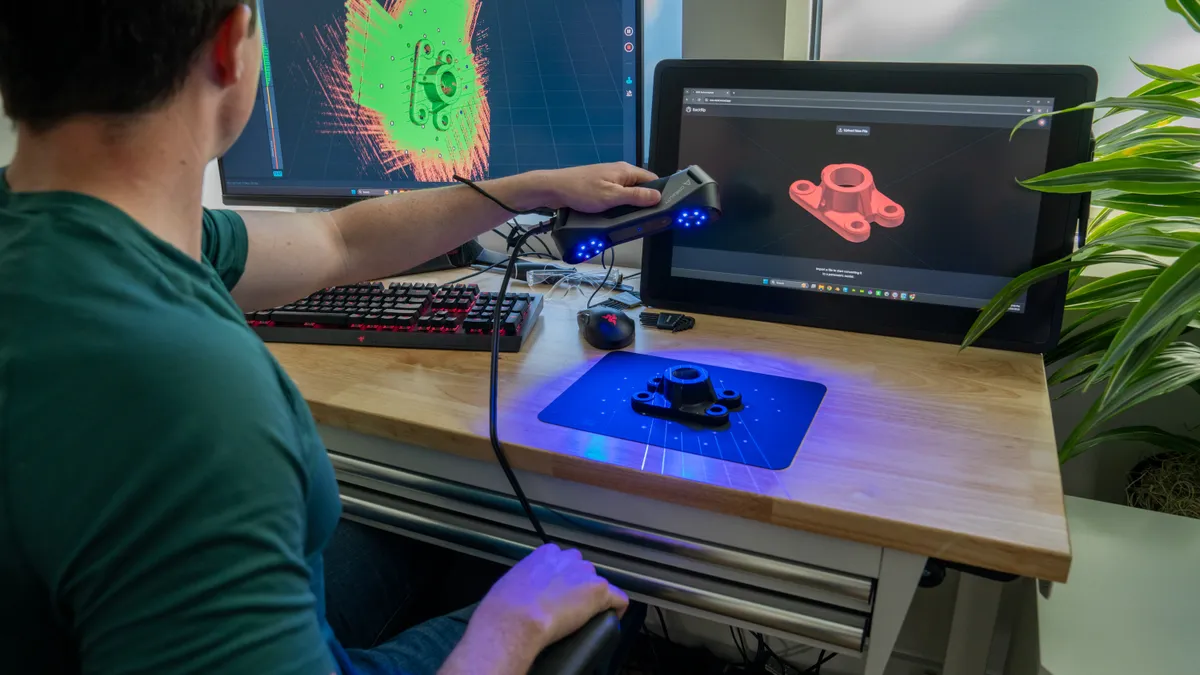

“We’re going to continue to invest in our factories, deploying automation where it makes sense and smart factory and further reducing structural costs by closing three to five plants,” Watson said.

Since 2019, the company has also reduced the cycle times of its manufacturing processes, such as lowering steel blank processes at its Solon, Ohio, plant from 171 to five.

Moreover, supply chain planning tools helped Kennametal reduce lead times as well as lower inventory, which Watson said improved its customer service and cash flow.

The machinery and materials maker is also looking to pursue M&A, which Watson said Kennametal hasn’t done in years. However, Kennametal has been increasing its focus on M&A as the manufacturer rebuilds its corporate development capabilities.

“When we’re looking at acquisitions, we’re going to be looking at acquisitions that prove access to markets, give us products into the portfolio that we find useful would add something to us,” Watson said. “We’ll be looking at things that are right in the core and near adjacencies. Importantly, these targets will emerge in a creative, have attractive organizational cultures and offer us the potential to realize significant synergies.”