Dive Brief:

- The Federal Aviation Administration is increasing its oversight of Boeing's production and manufacturing a week after an Alaska Airlines 737-9 Max plane door plug blew out midair.

- The agency will audit Boeing's 737-9 Max production line and suppliers to evaluate quality assurance compliance, as well as increase monitoring of the planes' in-service events, it announced Friday.

- The FAA will also assess safety risks around "delegated authority and quality oversight" and consider whether to move these functions to independent third parties.

Dive Insight:

News of the FAA's stepped-up scrutiny comes two days after the agency launched an investigation into the Alaska Airlines incident and Boeing's possible failure to meet quality and safety requirements.

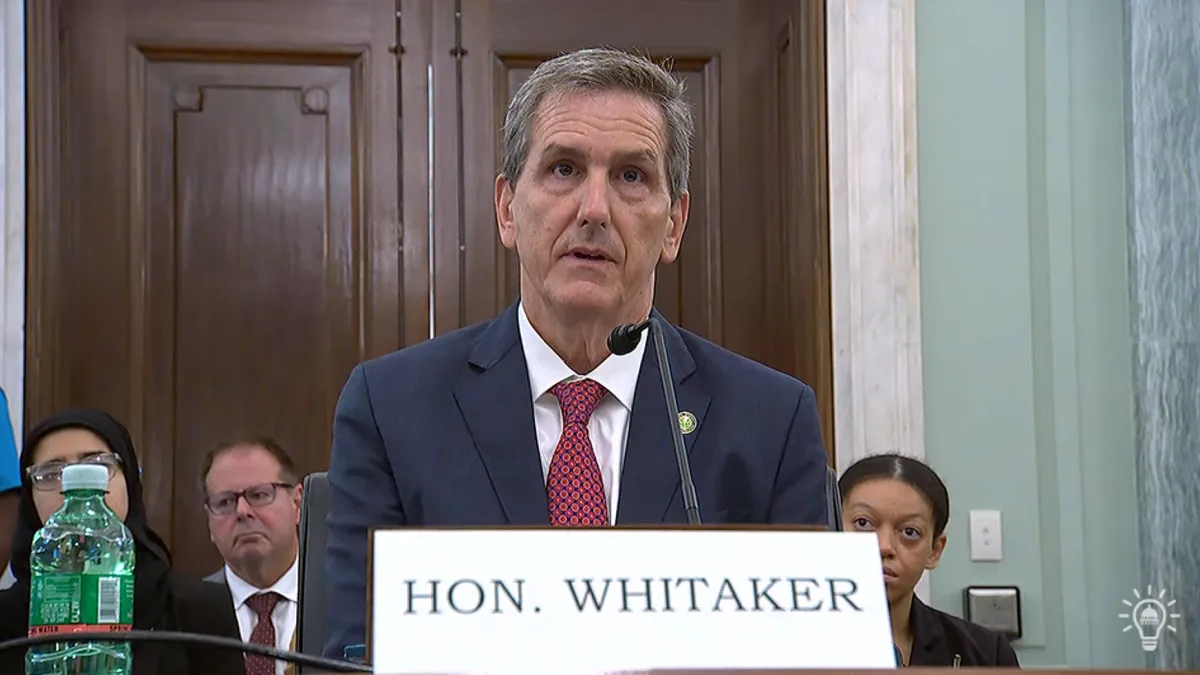

"It is time to re-examine the delegation of authority and assess any associated safety risks," FAA Administrator Mike Whitaker said in a statement Friday. "The grounding of the 737-9 and the multiple production-related issues identified in recent years require us to look at every option to reduce risk."

Boeing has been under intense scrutiny since last Friday, when a door plug panel detached from the fuselage of a 737-9 Max aircraft operated by Alaska Airlines. The blowout led to a gaping hole in the middle of the aircraft roughly 10 minutes into the flight and prompted an emergency landing.

The incident quickly sparked manufacturing and production quality concerns regarding Boeing and its supplier Spirit AeroSystems. Spirit manufactures nearly 70% of the 737 aircraft body, including its fuselage, wing leading edges and parts of the engine. A part of the fuselage plug area was found in a backyard in Oregon on Sunday following the incident, Reuters reported.

The FAA grounded roughly 171 Boeing aircraft the next day and will keep every 737-9 Max with a door plug out of the air until each can be cleared to fly safely, according to a Jan. 9 update.

Boeing CEO Dave Calhoun said in a company meeting this week that a Boeing technical team is supporting the National Transportation Safety Board investigation into the incident.

“This stuff matters,” Calhoun said. “Everything matters. Every detail matters.”

Spirit AeroSystems said in a Jan. 8 statement it is a committed Boeing partner on the 737 program and will work with the company on the issue. “At Spirit AeroSystems, our primary focus is the quality and product integrity of the aircraft structures we deliver,” the manufacturer said.

Boeing's recent history of quality woes

After the Alaska Airlines accident, the FAA was informed of additional discrepancies on other 737-9 airplanes. The possibility of other safety problems sparked an investigation to determine if Boeing “failed to ensure its completed products conformed to its approved design and were in a condition for safe operation in accordance with quality system inspection and test procedures,” according to its Jan. 10 letter to the company regarding the investigation launch.

On Dec. 28, for instance, the FAA reported it was inspecting targeted 737 Max aircraft to look for a possible loose bolt in the rudder control system.

“Boeing recommended the inspections after an international operator discovered a bolt with a missing nut while performing routine maintenance on a mechanism in the rudder-control linkage,” the FAA reported. “The company discovered an additional undelivered aircraft with a nut that was not properly tightened.”